June 8, 2010 – A slew of announcements and developments out of IMEC’s Technology Forum (June 7-8, Leuven, Belgium) span the gamut from facilities expansion to GE photovoltaics and gas sensor devices.

Expanded cleanrooms for chip, PV work

IMEC has officially opened its new 18,000 sq. m cleanroom/office setup at its campus in Leuven, Belgium, and is building a new office building as part of further expansions to bring its research campus to a total of 80,000 sq. m, "that can stand comparison with any other high-tech research center worldwide," the company says.

The total 10,000 sq. m cleanroom (1200 sq. m is "ultraclean") includes several key areas of leading-edge semiconductor manufacturing, including being "450mm-ready." First equipment in the space include a TEL CleanTrack Lithius Pro coater/developer, arrived in May, that will interface with ASML’s newest NXE:3100 EUV lithography scanner due to be delivered by year’s end.

Along with the new cleanroom, IMEC has started construction of new lab spaces (1600 sq. m) for research on silicon- and organic solar cells (to be "gradually installed"), and on biomedical electronics, including a recently launched NERF initiative, to be finalized by 1Q11. In addition, a new 16-floor office building with auditorium and light-equipment labs, is being laid out with construction planned for 4Q10.

Better Ge-based TPV

IMEC says it has devices a better way to make germanium-based thermophotovoltaic (TPV) cells, fabricated on substrates "with an optimized surface," that significantly reduces their cell costs.

TPV cells, which convert radiation from heat sources (temperatures lower than the sun’s temperature), are generally best suited for industrial uses, e.g. generating electricity from waste heat released from steel or glass production. They can also be incorporated into domestic heating systems to cogenerate electricity besides hot water, and thus can reduce waste (and increase efficiency) of domestic heating systems. But due to complexity of full TPV systems and relatively high cost of existing suitable cells, TPV systems haven’t gained traction in either industrial or consumer use.

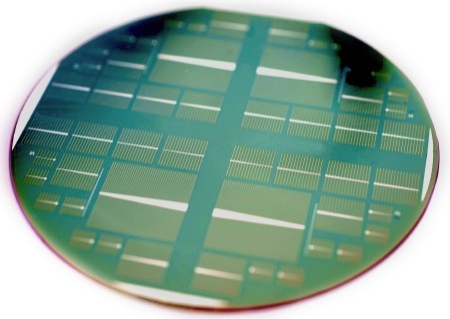

|

| IMEC’s germanium-based thermophotovoltaic cell with an optimized front and rear surface finishing. (Source: IMEC) |

Enter IMEC and its new fabrication process, which leverages the group’s work in surface passivation techniques, novel contacting technologies, and materials knowledge. Germanium-based TPV cells — well-suited as receivers due to their bandgaps, which are relatively close to the emission peaks of TPV selective emitters — are typically fabricated on epi-ready substrates originally made for epitaxial growth of III-V layers. But IMEC’s new method uses no epi deposition steps — the emitter is formed by diffusion and passivation, through use of amorphous Si.

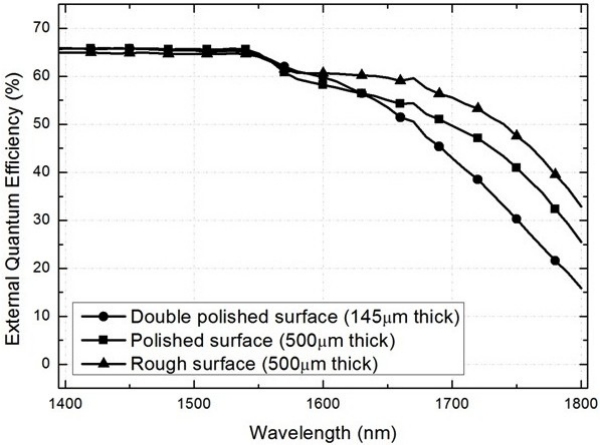

Specifically designed Ge substrates have been manufactured and tested, with spectral response measurements showing TPV cells on specifically engineered Ge substrates possess "remarkably better quantum efficiency" than traditional TPV cells with epi-ready substrates, IMEC notes — and this translates into higher waste heat to electric conversion efficiency.

|

| TPV cells on specially engineered substrates show improved performance at wavelengths relevant for thermophotovoltaic applications. (Source: IMEC) |

Exascale computing lab to gauge "space weather"

IMEC, with Intel and the Flemish Agency for Innovation by Science and Technology (IWT) and five Flemish universities (U. of Antwerp, Ghent U., Hasselt U., Katholieke Universiteit Leuven, and Vrije Universiteit Brussel), have opened an "ExaScience" lab in Leuven, Belgium, eyeing collaborative work in power reduction and reliability in supercomputer architecture, and 1000× faster performance to "exascale levels."

The lab, hosted at IMEC with initially two dozen researchers (adding another dozen by 2012), will develop software to run on Intel-based exascale computers, which will use up to 1M cores and 1B processes. Exascale computers’ massive output also means they generate a lot of heat and "require a power plant" to run, not to mention the complexity of getting all the cores and processes to work together harmoniously; thus new programming methods and software will be required for power consumption and fault tolerance.

First application for the ExaScience lab will be to predict "space weather," i.e. electromagnetic activity surrounding Earth’s atmosphere and its effects to safety and security here on the planet’s surface. An example: solar flares, which can cause havoc with electric power networks, pipelines, and wireless communications.

"We are excited to embark on this innovative collaboration in Flanders, bringing together scientific expertise in the fields of space weather prediction, computational simulation, reliability, visualization and performance modeling," said Stephen Pawlowski, Intel Senior Fellow and GM of its central architecture and planning unit, in a statement.

"By sharing our expertise, I’m convinced that the Flanders ExaScience Lab will bring valuable software solutions for Intel’s future exascale computer", added Luc Van den hove, IMEC president/CEO.

"Electronic nose" for gas sensing

IMEC and the Holst Center say they have created integrated sensing elements that can detect ppm-level concentrations of gas vapors.

Wireless sensor nodes for chemically detecting gaseous compounds are gaining favor for applications such as food monitoring, and healthcare and safety. For gas-sensing in an uncontrolled environment, vapors are identified using multiple sensing elements in a system dubbed an "electronic nose," which includes integrated low-power detectors with individually tuned chemical coatings. Current products including chemi-resistors and quartz crystals are not scalable or power-efficient enough for such low-power, small-formfactor devices.

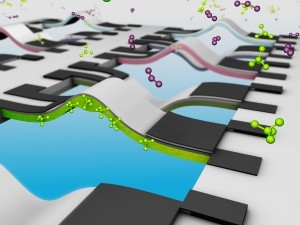

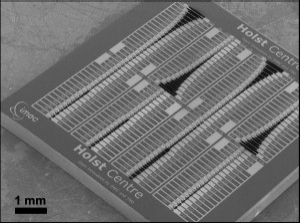

The new devices from IMEC and Holst offer microbridges with embedded individual piezoelectric "shakers" in a high-density array, with what they claim is "very high fabrication yield." Absorbents can be rapidly coated on the individual microbridges using commercial inkjet technology. The suspended structures vibrate individually; changes in their resonances are monitored as an indication of vapor absorption in their coatings. The microbridges’ very high length-to-thickness ratio enables high sensitivity to low-concentration vapors, IMEC says. The devices also incorporate integrated piezoelectric read-out schemes, to demonstrate ultralow-power operation.

|

|

Left: Closely-packed array of individually vibrated microbridge resonators can be used for separation of gases upon application of specific coatings. Right: The scanning electron microscope image of a complete sensor chip (9mm × 9mm) consisting of 160 unique individually addressable micromechanical resonators, with aspect ratios (length/thickness) ranging from 140-1500. (Source: IMEC)

Current work targets integrating the structures with low-power analog readout circuits and demonstrating simultaneous measurements from multiple structures. Applications range widely, from wine-and-cheese monitoring to "sniffing out" things like asthma, lung cancer, and kidney diseases.

COBRA for 4G devices

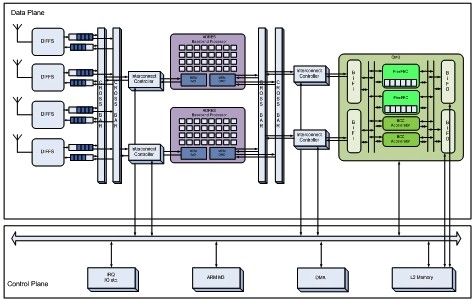

IMEC has introduced a cognitive baseband radio (COBRA) architecture for mobile handsets and wireless devices targeting 4G requirements (up to 1Gbit/s throughput and multiple asynchronous concurrent streams), offering a low-cost flexible architecture for mobile handsets and battery-powered wireless connectivity devices.

This particular COBRA architecture, designed with industrial partners of IMEC’s "green radio" program, incorporates IMEC’s energy-efficient high-performance ADRES reconfigurable baseband processor, with multi-threading and wide SIMD (single instruction, multiple data) capabilities, and well as associated tools for C-based compilation, as well as assisted parallelization over multiple cores and/or threads. A low-power flexible forward-error correction (FlexFEC) processor template achieving high-speed turbo and LDPC is also included. An LDPC-specific instance for multi-standard broadcasting has been derived to further optimize power and area. The device also incorporates novel ASIP (application-specific integrated processor)-based digital front-end enabling flexible filtering synchronization and spectrum sensing, a component that enables hierarchical platform activation and idle power in the range of 2mW in 65nm low-power CMOS technology for the baseband platform.

"With every new generation of mobile communication devices we expect more flexibility and more intelligence — devices that can negotiate and switch between frequencies to optimally use the available spectrum; devices that switch between standards, choosing the best option depending on location, user environment and user application," said Liesbet Van Der Perre, IMEC program director of wireless communication, in a statement. "Imec’s COBRA technology is an answer to that need, offering high flexibility combined with the energy efficiency needed in mobile devices."

|

| COBRA, IMEC’s reconfigurable baseband platform architecture. (Source: IMEC) |

IMEC-TSMC wafer shuttles to 40nm

IMEC and TSMC have extended IMEC’s Europractice IC service with TSMC’s 40nm general-purpose and low-power CMOS technologies. Both companies will offer TSMC’s Cybershuttle multiproject wafer (MPW) platform for IC prototyping and production services to European companies and academia.

Europractice, an EC-funded project in the frame of FP7, works with IC foundries to buy/share low-cost MPW services, in which several teams combine various IC designs onto wafers, thus enabling groups to share resources to make small quantities of designs at relatively low costs. Target groups include "universities, research centers, start-up companies, and companies with small niche markets," the companies say.

"Extending the partnership with imec enhances our ability to support the growing Innovation in the European semiconductor industry, particularly of Small and Medium Enterprises, and enables European academia and research institutes to access TSMC’s advanced technology offerings," said Maria Marced, president of TSMC Europe, in a statement.