July 11, 2010 — With continued device geometry and new process steps comes increasing use and variety of CMP steps — e.g. through-silicon vias (TSV), ceria used for shallow-trench isolation, very thin interlayer dielectrics, colloidal silica for copper steps, copper barrier steps. These also mean an increasing need to find and eliminate (or better yet, prevent) wafer defects and yield losses, including particles. Newer slurries being introduced and used in chemical mechanical planarization (CMP) are more densely packed with particles that can cause defect and damage and impact processing yield, and it’s a challenge to find them — both small and larger ones. Enter Vantage Technology, which is debuting at this week’s SEMICON West (South Hall, booth #425) a new slurry particle measurement technology, SlurryScope (patented in the US and internationally), to provide undiluted real-time measurement of industry-standard production slurries.

Often fabs measure highly diluted samples of their slurry (e.g. Ceria or colloidal silicas) to collect data on particle size distribution. Quantifying the impact of damaged/scrapped wafers due to CMP slurry agglomeration is difficult to divine, but it’s often in the top-10 pareto of wafer processing among leading IC and foundry operations, explains Marty Mason, EVP of sales and marketing — from 2%-3% yield impact up to 10% for newer designs, and applications requiring multiple finished wafers (e.g. TSV) compound the problem of any scratches or defects. And current equipment can’t measure those slurries due to high large particle counts (LPC) in a mean range (mostly <1μm) of abrasive particles. Some LPCs are known to be "soft" (i.e., no impact to the process), vs. the "hard" LPCs that can cause grooves, gouges, etc. — but without knowing the entire mechanisms behind all LPCs, the safest step is to get all of them out, a problem for CMP suppliers, Mason noted. "We don’t have a good understanding of what the LPCs actually are" — larger versions of the "good" desired abrasive particulates, or are they agglomerations, or even contaminants? Do they form when the slurry is shipped or stored, or run through certain pumping systems? Are they in all slurries?

Conventional slurry monitoring systems have to significantly dilute (>>100×) ceria and colloidal silica to measure particles, and generally they still can’t measure large particle counts, explains Mason. "They can only take small sample amounts from large batches [50-100mL] of slurry, and hope that it represents the bulk of the slurry," he explains. "But we measure it all, as it flows through" — without any dilution — and provide particle size distribution of the slurry with each snapshot of integration (~2-10sec). Existing tools to determine particulates in CMP slurry have "been around for years," employing tactics like light scattering, laser diffraction, etc. — methods that all break down and can’t measure heavy thick slurries. Dilution hasn’t really solved that problem, because that affects not just the particle count but also pH, stability, and reliability.

Vantage’s answer: measure the slurry in real-time as it goes to each and every wafer, and correlate the data to the exact wafer, not just a sampling every few hours. This constant monitoring (up to 300ml/min ) can help flag any high counts before too many wafers get impacted. "You can see the trend of particles vs. wafer results, wafer by wafer, how large particle count changes might impact wafer yield, damage, scratching, etc." Toolmakers like this idea, he points out, because it can show that the slurries — and not the processing tool — is responsible for any damage or loss. That also means more responsibility/risk shifted to slurry suppliers…some of whom have been receptive to Vantage’s monitoring technology; others, not so much.

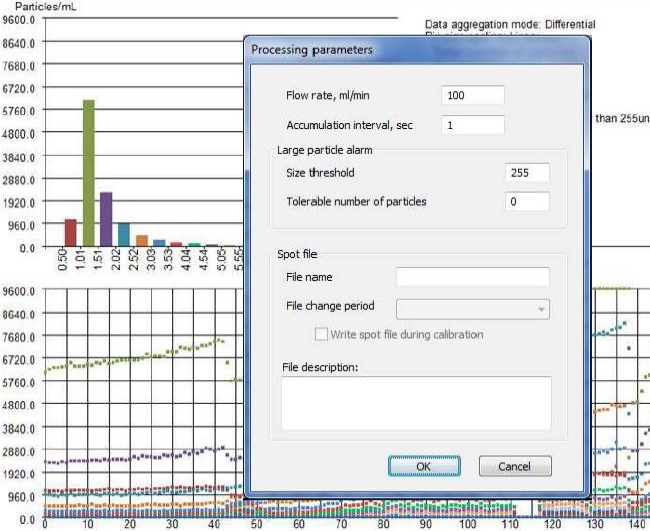

The company’s SlurryScope shows a real-time plot of bin sizes counting the number of particles every few tenths of a second, and a historical summary of bins over time as the slurry flows past (Figure 1). Users can set up an "alarm threshold" of bin activity (silicas hardly ever change, but colloidal and ceria particle counts "can move around," Mason notes). Others have also tried to develop systems that better identify and track undiluted slurries in real-time, but one had problems managing buildup (requiring stoppage and cleaning, making it impractical) and the other wasn’t able to achieve results repeatedly, Mason said. Vantage claims to avoid the buildup problem with its flow-through process (not periodic samples) and flushing with DI water; other parts of its technology involve "different techniques on light and optics that haven’t been used before," but Mason declined to discuss them, except to invoke some patents assigned to the company’s CTO Rashid Mavliev.

|

|

Figure 1. SlurryScope software interface. (Source: Vantage) |

The San Jose-based company has been working jointly with "select customers" in IC manufacturing, slurry makers, and IC/foundry operations to develop "a closed-loop approach" to slurry monitoring to protect wafers from large particles, and to track variations in slurry particle distribution and correlate them to wafer yields. Mason said the company has received "good interest" from multiple customers in the US and Asia, taking samples from both IC and slurry companies. So far data collection has been in the subfab where slurry distribution lies come from the tank and go out to the fab area — not on the platen at actual production, which will require a lot more integration of monitoring with IC company’s database, and other types of CMP-related measurements already being taken coming in and going out of tools (e.g. removal rate, uniformity, particles). Entering this workflow at the point before slurry hits the wafer — "that’s where we need to go next," Mason said.

One potential customer expressing interest in collaboration is SVTC — both to help collect and monitor data for their development customers but also the equipment companies. It also helps that with SVTC’s customers, most of whom are still at early development, "they don’t use a whole bunch of unique slurry, just what the customer gives them, e.g. off-the-shelf stuff," he added.

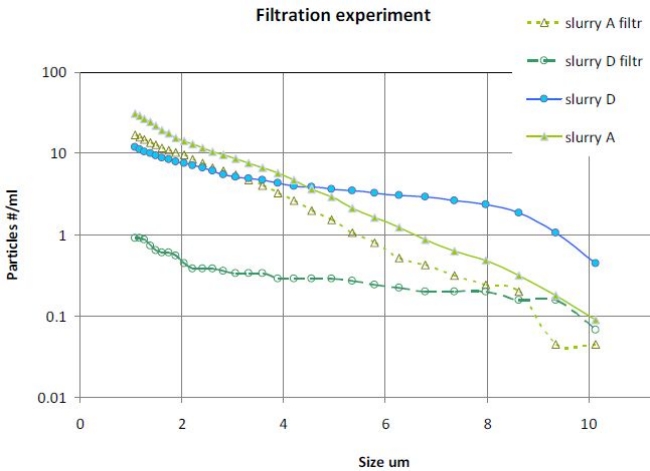

Mason also identified another area of benefit for the CMP monitoring system (Figure 2). "If we identify LPCs to avoid damage, it’s a payback" to customers, Mason noted. "But if we show them how to extend filter lifetimes, that’s another payback" — either slashing the cost of filters, or revealing if a filter needs to be changed more often. — J.M.

|

|

Figure 2. Effects of filters on particle measurement. (Source: Vantage) |