April 7, 2011 — Zymet Inc. introduced a reworkable edgebond adhesive, UA-2605, that improves thermal cycle performance of CBGAs and plastic BGAs.

In one trial, UA-2605 tripled the 0°C to +100°C performance of a CBGA, to nearly 2500 cycles. Previously, underfill was needed to achieve this level of performance, Zymet says.

|

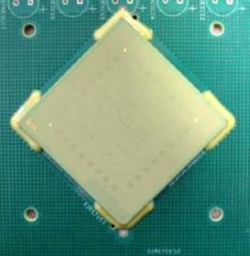

| Figure 1. Edgebonded CBGA. |

The edgebond adhesive is easier to process than an underfill. When applying underfill, the printed circuit board (PCB) is preheated to facilitate capillary flow, and multiple dispense passes are used to deposit sufficient material. With UA-2605, only four beads of the adhesive are required, one at each corner. There is no need to preheat the PCB, wait for underfill flow, and make multiple dispensing passes.

|

|

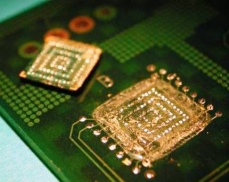

Figure 2. After removal of underfilled BGA, underfill residues must be removed. |

Reworking an underfilled BGA is a time consuming and delicate task. Underfill residues must be removed and, for fine-pitch BGAs, the risk of pad damage is high. With UA-2605, BGA rework is simple and straightforward. The temperature is raised and the adhesive is scraped away; then, the BGA is reflowed and lifted from the board. Little site cleaning is necessary.

Zymet is a manufacturer of microelectronic and electronic adhesives and encapsulants. Its products include die attach adhesives, substrate adhesives, UV curable glob top and cavity-fill encapsulants, and underfill encapsulants.

For more information, visit www.zymet.com.

Subscribe to Solid State Technology/Advanced Packaging.

Follow Advanced Packaging on Twitter.com by clicking www.twitter.com/advpackaging. Or join our Facebook group