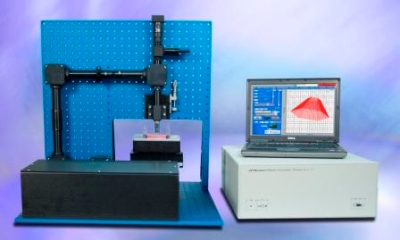

May 25, 2011 — Newport Corporation, lasers and photonics technology provider, introduced the Laser µFAB tabletop laser microfabrication workstation for researchers. Equipped with submicron resolution and a large stage, the tool can perform polymerization and ablation for MEMS, microelectronics, and other applications.

The Laser µFAB is designed for use in additive and subtractive processes, including two-photon polymerization (TPP) during 3D microfabrication, laser ablation and surface structuring of various materials, volumetric writing, and nanosurgery/microdissection. Researchers use TPP to develop photoresists for photonics, microelectronics, and MEMS. The tool ablates and structures metals, polymers, semiconductors, glasses, ceramics, and biological targets. Waveguides and microfluidics can be volumetrically written in glass or polymer substrates.

The Laser µFAB is designed for use in additive and subtractive processes, including two-photon polymerization (TPP) during 3D microfabrication, laser ablation and surface structuring of various materials, volumetric writing, and nanosurgery/microdissection. Researchers use TPP to develop photoresists for photonics, microelectronics, and MEMS. The tool ablates and structures metals, polymers, semiconductors, glasses, ceramics, and biological targets. Waveguides and microfluidics can be volumetrically written in glass or polymer substrates.

The Laser µFAB can be configured for use with femtosecond laser oscillators, amplifiers, OPAs, and other types of lasers in the visible to near-infrared (VIS-NIR) range. Sub-micron spot sizes are achieved at the sample with high numerical aperture (NA) objectives. Simple lenses can be used in applications where larger (10-20µm) spot sizes are acceptable. Computer-controlled variable attenuation integrated with the workstation prevents over or under exposure at the sample.

The standard Laser µFAB’s high-precision stages cover 100mm X/Y and 4.8mm Z, with 50nm resolution. This allows for continuous large area patterning without stitching. The top plate’s holder accomodates wafers, slides, cover slips, and other large samples.

Newport Corporation is an advanced-technology products and systems supplier to scientific research, microelectronics manufacturing, aerospace and defense/security, life and health sciences and precision industrial manufacturing markets. For additional information, visit www.newport.com/TAC-PR01

Follow Small Times on Twitter.com by clicking www.twitter.com/smalltimes. Or join our Facebook group