April 18, 2011 – BUSINESS WIRE — Rudolph Technologies Inc. (NASDAQ: RTEC), process characterization equipment and software provider for wafer fabs and advanced packaging facilities, launched the F30 Advanced Macro Inspection Module in its Explorer Inspection Cluster product line. Multiple F30 Inspection Modules have been purchased in recent weeks, and several are already installed in high-volume semiconductor manufacturing facilities.

The F30 module offers improved throughput over the entire sensitivity range when compared to previous generation tools, said Scott Balak, Rudolph’s director of front-end inspection products. The hardware platform is capable of supporting 450mm development and accomodating future requirements. The F30 Module combines automated set up and intelligent software on a flexible platform.

Two European fabs, a leading Asian foundry, a leading MEMS producer, and a process equipment manufacturer that is developing an integrated inspection solution have ordered the Rudolph system.

Rudolph Technologies Inc. designs, develops, manufactures and supports defect inspection, process control metrology, and data analysis systems and software used by semiconductor device manufacturers worldwide. The company’s yield management solutions are used in both the wafer processing and final manufacturing of ICs, as well as in emerging markets such as LED and Solar. Additional information can be found at www.rudolphtech.com.

Subscribe to Solid State Technology/Advanced Packaging.

Follow Solid State Technology on Twitter.com via editors Pete Singer, twitter.com/PetesTweetsPW and Debra Vogler, twitter.com/dvogler_PV_semi.

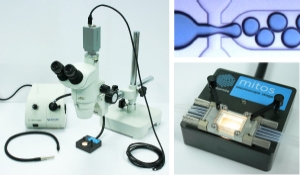

The range of optical systems includes a high-speed camera and microscope system, providing a flexible solution for general microscopy including droplet generation and particle imaging. The system’s microscope offers zoom ratio of 7.5:1 and good working distance for a range of samples. The camera integrates with the microscope to capture images at over 1000 frames per second. The universal stand enables flexible microscope positioning.

The range of optical systems includes a high-speed camera and microscope system, providing a flexible solution for general microscopy including droplet generation and particle imaging. The system’s microscope offers zoom ratio of 7.5:1 and good working distance for a range of samples. The camera integrates with the microscope to capture images at over 1000 frames per second. The universal stand enables flexible microscope positioning.