May 11, 2011 — Scientists at the U.S. Department of Energy’s (DOE) Brookhaven National Laboratory have assembled nanoscale pairings of fullerenes and quantum dots, controlling particle size and arrangement precisely so as to better understand how these two-particle systems convert light to electricity.

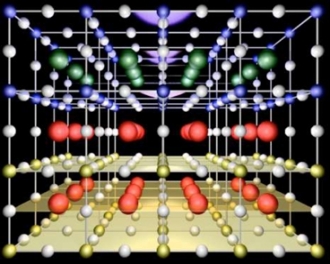

This is a hybrid inorganic/organic, dimeric (two-particle) material that acts as an electron donor-bridge-acceptor system for converting light to electrical current, said Brookhaven physical chemist Mircea Cotlet, lead author of a paper describing the dimers and their assembly method in Angewandte Chemie (Access the article here: http://onlinelibrary.wiley.com/doi/10.1002/anie.201007270/abstract).

By varying the length of the linker molecules and the size of the quantum dots, the scientists can control the rate and the magnitude of fluctuations in light-induced electron transfer at the level of the individual dimer. The dimers could lead to power-generating units for molecular electronics or more efficient photovoltaic solar cells, said Cotlet, who conducted this research with materials scientist Zhihua Xu at Brookhaven’s Center for Functional Nanomaterials (CFN).

|

|

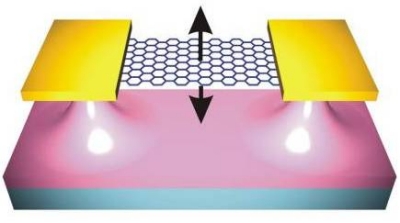

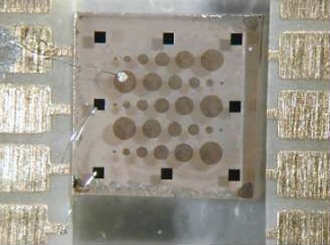

Figure. Left: Photoinduced electron transfer occurring in quantum dot-bridge-fullerene hererodimers and observed with single molecule microscopy. Right: Control of electron transfer (ET) rate by variation of interparticle distance (R, upper panel) and quantum dot size (D, lower panel).

|

Organic donor-bridge-acceptor systems have a range of charge transport mechanisms because their charge-transfer properties can be controlled by varying their chemistry. Recently, quantum dots have been combined with electron-accepting materials such as dyes, fullerenes, and titanium oxide to produce dye-sensitized and hybrid solar cells in the hope that the light-absorbing and size-dependent emission properties of quantum dots would boost the efficiency of such devices (so far, the power conversion rates of these systems have remained quite low). "Studying the charge separation and recombination processes in these simplified and well-controlled dimer structures helps us to understand the more complicated photon-to-electron conversion processes in large-area solar cells, and eventually improve their photovoltaic efficiency," Xu said.

|

| Zhihua Xu (seated) and Mircea Cotlet (standing). |

"Efforts to understand the processes involved so as to engineer improved systems have generally looked at averaged behavior in blended or layer-by-layer structures rather than the response of individual, well-controlled hybrid donor-acceptor architectures," said Xu.

The precision fabrication method developed by the Brookhaven scientists allows them to carefully control particle size and interparticle distance so they can explore conditions for light-induced electron transfer between individual quantum dots and electron-accepting fullerenes at the single molecule level.

The entire assembly process takes place on a surface and in a stepwise fashion to limit the interactions of the components (particles), which could combine in a number of ways if assembled by solution-based methods. This surface-based assembly also achieves controlled, one-to-one nanoparticle pairing.

To identify the optimal architectural arrangement for the particles, the scientists strategically varied the size of the quantum dots — which absorb and emit light at different frequencies according to their size — and the length of the bridge molecules connecting the nanoparticles.

For each arrangement, they measured the electron transfer rate using single molecule spectroscopy.

The scientists found that reducing quantum dot size and the length of the linker molecules led to enhancements in the electron transfer rate and suppression of electron transfer fluctuations.

"This suppression of electron transfer fluctuation in dimers with smaller quantum dot size leads to a stable charge generation rate, which can have a positive impact on the application of these dimers in molecular electronics, including potentially in miniature and large-area photovoltaics," Cotlet said.

A U.S. patent application is pending on the method and the materials resulting from using the technique, and the technology is available for licensing. Contact Kimberley Elcess at (631) 344-4151, [email protected], for more information.

This work was funded by the DOE Office of Science.

The Center for Functional Nanomaterials at Brookhaven National Laboratory is one of the five DOE Nanoscale Science Research Centers (NSRCs), premier national user facilities for interdisciplinary research at the nanoscale. Together the NSRCs comprise a suite of complementary facilities that provide researchers with state-of-the-art capabilities to fabricate, process, characterize and model nanoscale materials, and constitute the largest infrastructure investment of the National Nanotechnology Initiative. The NSRCs are located at DOE’s Argonne, Brookhaven, Lawrence Berkeley, Oak Ridge and Sandia and Los Alamos national laboratories. For more information about the DOE NSRCs, please visit http://nano.energy.gov.

One of ten national laboratories overseen and primarily funded by the Office of Science of the U.S. Department of Energy (DOE), Brookhaven National Laboratory conducts research in the physical, biomedical, and environmental sciences, as well as in energy technologies and national security. Learn more at http://www.bnl.gov

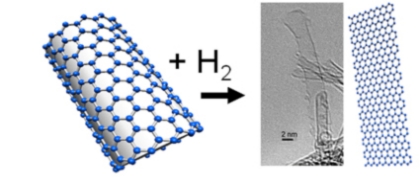

the edges, which can be an advantage for some applications. Alexandr Talyzin (pictured at left), physicist at Umeå University in Sweden, has over the past decade been studying how hydrogen reacts with fullerenes.

the edges, which can be an advantage for some applications. Alexandr Talyzin (pictured at left), physicist at Umeå University in Sweden, has over the past decade been studying how hydrogen reacts with fullerenes.