April 29, 2011 — Researchers at the National Institute of Standards and Technology (NIST) have shown that the electronic properties of two layers of graphene vary on the nanometer scale. The difference in the strength of the electric charges between the two layers varies across the layers. They also actually reverse in sign to create randomly distributed puddles of alternating positive and negative charges.

|

|

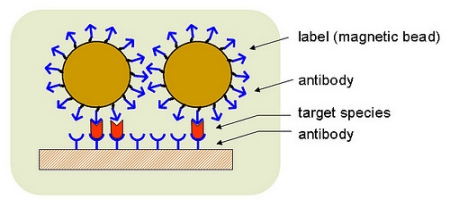

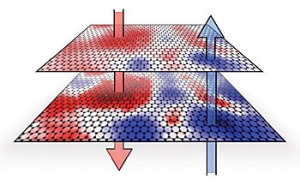

Figure. NIST measurements show that interactions of the graphene layers with the insulating substrate material causes electrons (red, down arrow) and electron holes (blue, up arrow) to collect in "puddles". The differing charge densities creates the random pattern of alternating dipoles and electon band gaps that vary across the layers. Credit: NIST |

Graphene, a single layer of carbon atoms, is prized for its remarkable properties, not the least of which is the way it conducts electrons at high speed. However, the lack of a band gap — an energetic threshold that makes it possible to turn a transistor on and off — makes graphene ill-suited for digital electronic applications.

Researchers have known that bilayer graphene, consisting of two stacked graphene layers, acts more like a semiconductor when immersed in an electric field.

According to NIST researcher Nikolai Zhitenev, the band gap may also form on its own due to variations in the sheets’ electrical potential caused by interactions among the graphene electrons or with the substrate (usually a nonconducting, or insulating material).

NIST fellow Joseph Stroscio says that their measurements indicate that interactions with the disordered insulating substrate material causes pools of electrons and electron holes (absence of electrons) to form in the graphene layers. Both electron and hole "pools" are deeper on the bottom layer because it is closer to the substrate. This difference in "pool" depths, or charge density, between the layers creates the random pattern of alternating charges and the spatially varying band gap.

Reported in Nature Physics, the new measurements bring graphene a step closer to being used in practical electronic devices. Manipulating the purity of the substrate could give researchers a way to finely control graphene’s band gap and may eventually lead to the fabrication of graphene-based transistors that can be turned on and off like a semiconductor.

Still, as shown in the group’s previous work (Jan. 19, 2011, Tech Beat article "Real-World Graphene Devices May Have a Bumpy Ride" at www.nist.gov/public_affairs/tech-beat/tb20110119.cfm#graphene), while these substrate interactions open the door to graphene’s use as a practical electronic material, they lower the window on speed. Electrons do not move as well through substrate-mounted bilayer graphene; however, this may likely be compensated for by engineering the graphene/substrate interactions.

Stroscio’s team plans to explore the role that substrates may play in the creation and control of band gaps in graphene by using different substrate materials. If the substrate interactions can be reduced far enough, says Stroscio, the exotic quantum properties of bilayer graphene may be harnessed to create a new quantum field effect transistor (FET).

G. Rutter, S. Jung, N. Klimov, D. Newell, N. Zhitenev and J. Stroscio. Microscopic polarization in bilayer graphene. Nature Physics. Published online April 24, 2011. Access the article here: http://www.nature.com/nphys/journal/vaop/ncurrent/full/nphys1988.html

The National Institute of Standards and Technology (NIST) is an agency of the U.S. Commerce Department. Learn more at www.nist.gov.

Also read: Graphene transistors cool off at the nano level

Follow Small Times on Twitter.com by clicking www.twitter.com/smalltimes. Or join our Facebook group