April 13, 2011 — In a paper published March 29 in the Proceedings of the National Academy of Sciences, Qiaoqiang Gan, PhD, an assistant professor of electrical engineering at the University at Buffalo’s (UB’s) School of Engineering and Applied Sciences, and his colleagues at Lehigh University, where he was a graduate student, described how they slowed broadband light waves using a type of material called nanoplasmonic structures.

The goal is to create multiplexed, multiwavelength communications, where optical data can potentially be tamed at different wavelengths, increasing processing and transmission capacity.

Gan notes that if light could ever be stopped entirely, new possibilities would open up for data storage.

"At the moment, processing data with optical signals is limited by how quickly the signal can be interpreted," he says. "If the signal can be slowed, more information could be processed without overloading the system."

Gan and his colleagues created nanoplasmonic structures by making nanoscale grooves in metallic surfaces at different depths, which alters the materials’ optical properties.

These plasmonic chips provide the critical connection between nanoelectronics and photonics, allowing these devices to be integrated for optical computing, "lab-on-a-chip" biosensors and more efficient, thin-film photovoltaic materials.

The optical properties of the nanoplasmonic structures allow different wavelengths of light to be trapped at different positions in the structure, potentially allowing for optical data storage and enhanced nonlinear optics. Conventional methods can only trap a single wavelength in a narrow band.

"Light is usually very fast, but the structures I created can slow broadband light significantly," says Gan, thanks to the structures’ engineered surface "plasmon resonances," where light excites the waves of electrons that oscillate back and forth on metal surfaces.

In this case, he says, light can be slowed down and trapped in the vicinity of resonances in this novel, dispersive structural material.

Gan and his colleagues also found that because the nanoplasmonic structures they developed can trap very slow resonances of light, they can do so at room temperature, instead of at the ultracold temperatures that are required in conventional slow-light technologies.

"In the PNAS paper, we showed that we trapped red to green," explains Gan. "Now we are working on trapping a broader wavelength, from red to blue. We want to trap the entire rainbow."

Gan, who was hired at UB under the UB 2020 strategic strength in Integrated Nanostructured Systems, will be working toward that goal, using the ultrafast light source in UB’s Department of Electrical Engineering in the laboratory of UB professor and vice president for research Alexander N. Cartwright.

"This ultrafast light source will allow us to measure experimentally just how slow is the light that we have trapped in our nanoplasmonic structures," Gan explains. "Once we know that, we will be able to demonstrate our capability to manipulate light through experiments and optimize the structure to slow the light further."

Co-authors with Gan on the study are Filbert Bertoli, Yongkang Gao, Yujie Ding, Kyle Wagner and Dmitri Vezenov, all of Lehigh University.

Follow Small Times on Twitter.com by clicking www.twitter.com/smalltimes. Or join our Facebook group

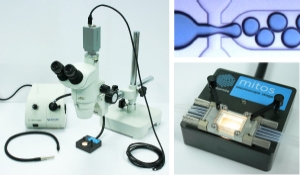

The range of optical systems includes a high-speed camera and microscope system, providing a flexible solution for general microscopy including droplet generation and particle imaging. The system’s microscope offers zoom ratio of 7.5:1 and good working distance for a range of samples. The camera integrates with the microscope to capture images at over 1000 frames per second. The universal stand enables flexible microscope positioning.

The range of optical systems includes a high-speed camera and microscope system, providing a flexible solution for general microscopy including droplet generation and particle imaging. The system’s microscope offers zoom ratio of 7.5:1 and good working distance for a range of samples. The camera integrates with the microscope to capture images at over 1000 frames per second. The universal stand enables flexible microscope positioning.