February 15, 2011 — The University of South Florida received $5.45 million in grants from the Bill & Melinda Gates Foundation to create advanced devices that mimic the human liver to better study the life cycle of the malaria parasite, and to develop effective therapies for the disease.

Malaria may be most vulnerable to attack in the liver stage. Human models fabricated on micromechanical systems could help accelerate the discovery of new drugs or even vaccines for Plasmodium vivax and Plasmodium falciparum, the two most common forms of malaria.

Effective therapeutics funded in the second grant target malaria preventions and cure by a long-term continuous culture system for P. vivax.

|

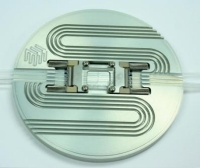

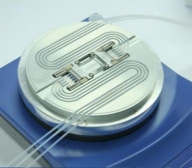

| Photo 1. A microfluidic device used to create human mimetic tissue models for testing potential malaria drugs. |

USF will collaborate with Draper Laboratory on the projects. The dynamic public-private partnership combines the USF Global Infectious Disease Research team’s expertise in malaria parasite biology and human model development with Draper’s extensive experience in tissue engineering and the development of human mimetic in vitro (laboratory) models. Draper Lab has been involved in MEMS research and development since 1984, including multiple biological applications.

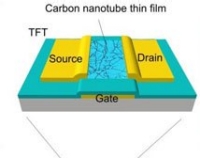

To create new models to mimic human body conditions in which malaria parasites replicate, the researchers are using Draper’s prototype microfluidic device technology. The microfluidic device consists of microscope slide-sized unit containing chambers through which fluid flow is maintained by a micro-pump. It is designed to support complex tissue growth, allowing liver or blood vessel cells to grow in three dimensions while experiencing physiologically relevant forces instead of on the static two-dimensional surface of a petri dish. This technology, previously unavailable in a lab setting, may also prove useful for screening large volumes of potential anti-malarial agents and evaluating their effectiveness. Also read: MEMS may screen metastatic breast cancer cells by mimicking environment

"The Draper models offer unique microenvironments, so cells grow and function more normally," said Dennis Kyle, Ph.D., professor of global health at the USF College of Public Health. "That’s important because one major roadblock to learning about the liver stage of the malaria parasite has been that the liver cells lose some of their basic functions and no longer metabolize drugs after a few days."

"We cannot eliminate one of the most prevalent causes of malaria in the world — Plasmodium vivax — unless we come up with new drugs or vaccines that target the dormant liver forms of the parasite," Dr. Kyle said. "Current tools– in vitro and animal models are either largely ineffective or cost-prohibitive in predicting which drugs may work best in humans. New human models are the basic building blocks needed to establish strong, credible drug and vaccine discovery programs, not only at USF but at other universities and companies working on new ways to fight malaria."

Dr. Kyle is the principal investigator for a three-year Gates Foundation grant seeking to develop human liver models that could more quickly and accurately test potential drug candidates for vivax and falciparum malaria. Draper Laboratory’s efforts will be overseen by principal investigator Joseph Cuiffi, PhD, of the Draper Bioengineering Center at USF. They are working with John Adams, Ph.D., professor of global health at USF; Jeffrey Borenstein, Ph.D., a Draper physicist and biomedical engineer; and Joseph Charest, Ph.D., a Draper biomedical engineer. The original work on this technology at Draper was funded by the Center for the Integration of Medicine and Innovative Technology of which Draper is a founding member.

|

|

Photo 2. Clockwise from left: Principal investigators Dr. John Adams and Dr. Dennis Kyle of USF Health are collaborating on the Gates Foundation-funded projects with Dr. Joseph Cuiffi, principal investigator at Draper Lab. |

Dr. Adams is the principal investigator for a three-year Gates Foundation grant that brings together a worldwide network of leading investigators with the skills and resources needed to create long-term blood stage cultures of vivax malaria. This form of malaria has proven particularly difficult to grow and sustain in the laboratory. Dr. Adams is working with Dr. Cuiffi and Dr. Kyle, as well Dr. Jetsumon (Sattabongkot) Prachumsri of the Vivax Research Center in the Faculty of Tropical Medicine, Mahidol University, and the Armed Forces Research Institute in Bangkok, Thailand; Dr. Peter Siba, director of the Papua New Guinea Institute for Medical Research; Dr. Louis Schofield, a Howard Hughes Medical Institute international research scholar at the Walter and Eliza Hall Institute of Medical Research in Australia; and Dr. Osamu Kaneko at Nagasaki University in Japan.

"To be able to replicate and study the entire malaria infection process outside the body will be critical in developing new drugs with the potential to eliminate malaria," said Draper’s Dr. Cuiffi.

Malaria and the liver

Malaria affects 10% of the world’s population, killing nearly one million people a year in developing countries and crippling their economies. In humans, the liver is the first target of the disease once a person is bit by an infected mosquito. The infecting parasites for most types of malaria multiply and rupture liver cells, escaping back into the bloodstream. In vivax malaria, some parasites can remain dormant in the liver for extended periods before infecting the blood. The parasites, now modified to attack red blood cells, rapidly create more parasites, which spread throughout the bloodstream in waves.

At this initial stage of human infection there are fewer parasites — hundreds or a few thousand in the liver compared to millions once parasites start replicating in the bloodstream. Vivax has the potential to lay dormant in the liver and re-activate months or years after treatment, causing relapses of malaria. While parasites are in the liver, the person does not feel sick. Once parasites enter the bloodstream, disease symptoms emerge. "The drugs available to treat the bloodstream stages don’t work in the liver," Dr. Adams said. "So if you could get rid of parasites in the liver stage, you could essentially prevent vivax malaria and the transmission of infection."

Third, the only drug effective in attacking the liver’s reservoir of dormant malaria parasites to help prevent recurrences of vivax malaria, Primaquine, is risky for widespread use. Administering Primaquine to people with a red blood cell enzyme deficiency, known as glucose phosphate dehydrogenase (G6PD) deficiency, may trigger severe and potentially lethal blood loss, Dr. Adams said. "There’s no good bedside test to identify G6PD-deficient individuals, and, unfortunately, this condition most often occurs in those areas where vivax malaria is endemic."

More information on Draper Laboratory MEMS work is available at http://www.draper.com/mems_background/index.html. Learn more about the University of South Florida at www.usf.edu

Follow Small Times on Twitter.com by clicking www.twitter.com/smalltimes. Or join our Facebook group