February 2, 2011 — Sun-drenched roofs, windows, deserts and even clothing will someday be integrated with inexpensive solar cells that are many times thinner and lighter than current options. It is not hard to envision a time when integrated solar technologies will be ubiquitous in our increasingly energy-hungry lives. A multidisciplinary team of Stanford engineers led by Mike McGehee, Yi Cui and Mark Brongersma, and joined by Michael Graetzel at the École Polytechnique Fédérale de Lausanne (EPFL), are focused on that goal.

The Stanford/EPFL team succeeded in harnessing plasmonics to more effectively trap light within thin solar cells to improve performance and production feasability. Results were published in Advance Energy Materials.

"Plasmonics makes it much easier to improve the efficiency of solar cells," said McGehee, an associate professor of materials science and engineering at Stanford, and director of CAMP, Center for Advanced Molecular Photovoltaics, a multidisciplinary, multi-university team tackling the challenges of thin-film solar cells.

"Using plasmonics we can absorb the light in thinner films than ever before," McGehee said. "The thinner the film, the closer the charged particles are to the electrodes. In essence, more electrons can make it to the electrode to become electricity."

|

| Figure 1. Acting like a waffle iron, silicon nanodomes, each about 300 nanometers in diameter and 200 nanometers tall, imprint a honeycomb pattern of nanoscale dimples into a layer of metal within the solar cell. Image courtesy of Michael McGehee. |

Plasmonics is the study of the interaction of light and metal. Under precise circumstances, these interactions create a flow of high-frequency, dense electrical waves rather than electron particles. The electronic pulse travels in extremely fast waves of greater and lesser density, like sound through the air.

To make the plasmonic dye-sensitized solar cell (DSSC), the team imprinted a honeycomb pattern of nanoscale dimples into a layer of metal within the solar cell, like a nanoscale waffle, with the bumps on the waffle iron as domes rather than cubes. McGehee and team members spread a thin layer of "batter" on a transparent, electrically conductive base. This batter is mostly titania, a semiporous metal that is also transparent to light. Next, they use their nano waffle iron to imprint the dimples into the batter. They then layer on a light-sensitive dye that oozes into the dimples and pores of the substrate. Lastly, the engineers add a layer of silver, which hardens almost immediately.

|

| Figure 2. Titania within the solar cell is imprinted by the silicon nanodomes like a waffle imprinted by the iron. Image courtesy of Michael McGehee. |

When all those nanodimples fill up, the result is a pattern of nanodomes on the light-ward side of the silver. This bumpy layer of silver has two primary benefits. First, it acts as a mirror, scattering unabsorbed light back into the dye for another shot at collection. Second, the light interacts with the silver nanodomes to produce plasmonic effects. Those domes of silver are crucial. Reflectors without them will not produce the desired effect. Nanodomes must be precisely the right diameter, height, and spacing to fully optimize the plasmonics. Read more about nanotechnology here.

Photons enter and pass through the transparent base and the titania, at which point some photons would be absorbed by the light-sensitive dye, creating an electric current. Most of the remaining photons would hit the silver back reflector and bounce back into the solar cell. A certain portion of the photons that reach the silver, however, will strike the nanodomes and cause plasmonic waves to course outward.

Dye solar cells typically reach 8% efficiency and 7 year life spans — significantly below photovoltaic industry standard of 25% efficiency, 20-30 year lifetime. Engineers like McGehee believe that if they can convert just 15% of the light into electricity and extend the product lifecycle to a decade, the roll-to-roll production, less toxic materials, flexibility, light weight, and other benefits of this emerging thin-film tech will outweigh the lower numbers.

Learn more at http://www.stanford.edu/

Courtesy of Andrew Myers, associate communications director for the School of Engineering, Stanford.

Also read: EU partners eye metallic nanostructures for solar cells

Subscribe to Photovoltaics World

Follow Photovoltaics World on Twitter.com via editors Pete Singer, twitter.com/PetesTweetsPW and Debra Vogler, twitter.com/dvogler_PV_semi.

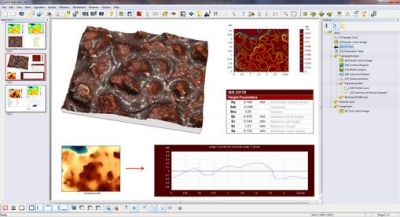

Entry-level Leica Map Start software is used in conjunction with LAS Montage. LAS Montage acquires a series of image planes at known spacing covering the in-focus region of a specimen with a Leica microscope. From this stack a depth map and an extended focus image are derived and analyzed by Leica Map. In Leica Map Start, surface topography can be viewed at any zoom level and any angle in real time. Color and intensity image overlays facilitate the location of surface features, including defects. Distances, angles, and step heights can be measured. Height and functional parameters are calculated in accordance with the latest ISO 25178 standard on areal surface texture. Optional modules can extend the capability to surface texture and contour analysis.

Entry-level Leica Map Start software is used in conjunction with LAS Montage. LAS Montage acquires a series of image planes at known spacing covering the in-focus region of a specimen with a Leica microscope. From this stack a depth map and an extended focus image are derived and analyzed by Leica Map. In Leica Map Start, surface topography can be viewed at any zoom level and any angle in real time. Color and intensity image overlays facilitate the location of surface features, including defects. Distances, angles, and step heights can be measured. Height and functional parameters are calculated in accordance with the latest ISO 25178 standard on areal surface texture. Optional modules can extend the capability to surface texture and contour analysis. The ANT95-R and ANT130-R rotary stages are available in 20°, 180°, or 360° continuous travel. Maximum speed is 200rpm and maximum acceleration is 400rad/s2. Axial load capacity is 2kg for the ANT95-R and 3kg for the ANT130-R. These rotary stages also offer an 11mm clear aperture that can be used for product feed-through, laser beam delivery, cable clearance, or application-specific requirements.

The ANT95-R and ANT130-R rotary stages are available in 20°, 180°, or 360° continuous travel. Maximum speed is 200rpm and maximum acceleration is 400rad/s2. Axial load capacity is 2kg for the ANT95-R and 3kg for the ANT130-R. These rotary stages also offer an 11mm clear aperture that can be used for product feed-through, laser beam delivery, cable clearance, or application-specific requirements. "The EBPG5000plusES is a 100kV high-performance system…It will enable us to address the nanotechnology development needs of natural sciences, applied sciences and engineering programs," says Dr. Volkan Özgüz, director of the Nanotechnology and Application Center.

"The EBPG5000plusES is a 100kV high-performance system…It will enable us to address the nanotechnology development needs of natural sciences, applied sciences and engineering programs," says Dr. Volkan Özgüz, director of the Nanotechnology and Application Center.