January 14, 2011 — A simple technique to make a common virus-killing material significantly more effective is a breakthrough from the Rice University labs of Andrew Barron and Qilin Li. Silicone grease, silica, or silicic acid can treat titanium dioxide nanoparticles for increased virus-killing efficiency.

Rather than trying to turn the process into profit, the researchers have put it into the public domain. They hope wide adoption will save time, money and perhaps even lives. The Rice professors and their team reported in Environmental Science and Technology, an American Chemical Society journal, that adding silicone to titanium dioxide, a common disinfectant, dramatically increases its ability to degrade aerosol- and water-borne viruses. Read the abstract at http://pubs.acs.org/doi/abs/10.1021/es102749e

|

| From left, Professor Qilin Li, graduate student Michael Liga, alumna Huma Jafry and Professor Andrew Barron have published a paper outlining their method to dramatically improve the effectiveness of a common disinfectant. |

|

"We’re taking a nanoparticle that everyone’s been using for years and, with a very simple treatment, we’ve improved its performance by more than three times without any real cost," said Barron, Rice’s Charles W. Duncan Jr.-Welch Professor of Chemistry and a professor of materials science. Barron described himself as a "serial entrepreneur," but saw the discovery’s potential benefits to society as being far more important than any thoughts of commercialization.

Barron said titanium dioxide is used to kill viruses and bacteria and to decompose organics via photocatalysis (exposure to light, usually ultraviolet). The naturally occurring material is also used as a pigment in paints, in sunscreen and even as food coloring.

"If you’re using titanium dioxide, just take it, treat it for a few minutes with silicone grease or silica or silicic acid, and you will increase its efficiency as a catalyst," he said.

Barron’s lab uses "a pinch" of silicon dioxide to treat a commercial form of titanium dioxide called P25. "Basically, we’re taking white paint pigment and functionalizing it with sand," he said.

Disinfecting a volume of water that once took an hour would now take minutes because of the material’s enhanced catalytic punch, Barron said. "We chose the Yangtze River as our baseline for testing, because it’s considered the most polluted river in the world, with the highest viral content," he said. "Even at that level of viral contamination, we’re getting complete destruction of the viruses in water that matches the level of pollution in the Yangtze."

Using a smaller amount of treated P25 takes longer but works just as well, he said. "Either way, it’s green and it’s cheap."

The team started modifying titanium dioxide two years ago. Li, an assistant professor in civil and environmental engineering whose specialties include water and wastewater treatment, approached Barron to help search for new photocatalytic nanomaterials to disinfect drinking water.

The revelation came when students in Barron’s lab heated titanium dioxide, but it wasn’t quite the classic "aha!" moment. Graduate student and co-author Michael Liga saw the data showing greatly enhanced performance and asked fellow graduate student Huma Jafry what she had done. Jafry, the paper’s first author, said, "I didn’t do anything." When Barron questioned Jafry, who has since earned her doctorate, he discovered she used silicone grease to seal the vessel of P25 before heating it. Subsequent testing with nonsilicone grease revealed no change in P25’s properties, whether the sample was heated or not. Remarkably, Barron said, further work with varying combinations of titanium dioxide and silicone dioxide found the balance between the two at the time of the discovery was nearly spot-on for maximum impact.

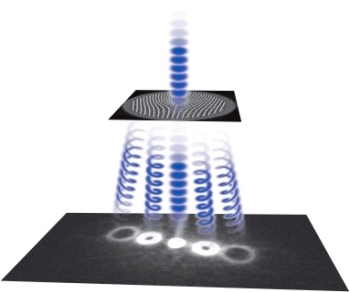

Barron said binding just the right amount of silica to P25 creates an effect at the molecular level called band bending. "Because the silicone-oxygen bond is very strong, you can think of it as a dielectric," he said. "If you put a dielectric next to a semiconductor, you bend the conduction and valence bands. And therefore, you shift the absorption of the ultraviolet (used to activate the catalyst)."

Bending the bands creates a path for electrons freed by the UV to go forth and react with water to create hydroxyl radicals, an oxidant responsible for contaminant degradation and the most significant reactive agent created by titanium dioxide. "If your conduction band bends to the degree that electrons find it easier to pop out and do something else, your process becomes more efficient," Barron said.

Li saw great potential for enhanced P25. In developed countries, photo reactors designed to take advantage of the new material in centralized treatment plants could more efficiently kill bacteria and inactivate viruses in water supplies while minimizing the formation of harmful disinfection byproducts, she said.

But the greatest impact may be in developing nations where water is typically disinfected through the SODIS method, in which water is exposed to sunlight for its heat and ultraviolet radiation.

"In places where they don’t have treatment plants or even electricity, the SODIS method is great, but it takes a very long time to make water safe to drink," Li said. "Our goal is to incorporate this photocatalyst so that instead of taking six hours, it only takes 15 minutes."

"Here’s a way of taking what is already a very good environmental catalyst and making it better," Barron said. "It works consistently, and we’ve done batch after batch after batch of it now. The methodology in the paper is the one we routinely use. As soon as we buy P25, we treat it."

The Robert A. Welch Foundation, the U.S. Navy and the National Science Foundation Center for Biological and Environmental Nanotechnology supported the research.

Follow Small Times on Twitter.com by clicking www.twitter.com/smalltimes. Or join our Facebook group

Teeth and bone are important and complex structures in humans and other animals, but little is actually known about their chemical structure at the atomic scale. What exactly gives them their renowned toughness, hardness and strength? How do organisms control the synthesis of these advanced functional composites?

Teeth and bone are important and complex structures in humans and other animals, but little is actually known about their chemical structure at the atomic scale. What exactly gives them their renowned toughness, hardness and strength? How do organisms control the synthesis of these advanced functional composites?

"At each stage, it’s possible there will be new roadblocks that will come up," noted Stephen Lippard, the Arthur Amos Noyes Professor of Chemistry and a senior author of the paper, which appears in the Proceedings of the National Academy of Sciences the week of Jan. 10. Additional animal testing is needed before the cisplatin-carrying particles can go into human clinical trials, says Farokhzad. "At the end of the day, if the development results are all promising, then we would hope to put something like this in humans within the next three years," he says.

"At each stage, it’s possible there will be new roadblocks that will come up," noted Stephen Lippard, the Arthur Amos Noyes Professor of Chemistry and a senior author of the paper, which appears in the Proceedings of the National Academy of Sciences the week of Jan. 10. Additional animal testing is needed before the cisplatin-carrying particles can go into human clinical trials, says Farokhzad. "At the end of the day, if the development results are all promising, then we would hope to put something like this in humans within the next three years," he says. Omid Farokhzad, associate professor at Harvard Medical School and director of the Laboratory of

Omid Farokhzad, associate professor at Harvard Medical School and director of the Laboratory of