Silicon has few serious competitors as the material of choice in the electronics industry. Yet transistors, the switchable valves that control the flow of electrons in a circuit, cannot simply keep shrinking to meet the needs of powerful, compact devices; physical limitations like energy consumption and heat dissipation are too significant.

Now, using a quantum material called a correlated oxide, Harvard researchers have achieved a reversible change in electrical resistance of eight orders of magnitude, a result the researchers are calling “colossal.” In short, they have engineered this material to perform comparably with the best silicon switches.

The finding arose in what may seem an unlikely spot: a laboratory usually devoted to studying fuel cells—the kind that run on methane or hydrogen—led by Shriram Ramanathan, Associate Professor of Materials Science at the Harvard School of Engineering and Applied Sciences (SEAS). The researchers’ familiarity with thin films and ionic transport enabled them to exploit chemistry, rather than temperature, to achieve the dramatic result.

Because the correlated oxides can function equally well at room temperature or a few hundred degrees above it, it would be easy to integrate them into existing electronic devices and fabrication methods. The discovery, published in Nature Communications, therefore firmly establishes correlated oxides as promising semiconductors for future three-dimensional integrated circuits as well as for adaptive, tunable photonic devices.

Challenging silicon

Although electronics manufacturers continue to pack greater speed and functionality into smaller packages, the performance of silicon-based components will soon hit a wall.

“Traditional silicon transistors have fundamental scaling limitations,” says Ramanathan. “If you shrink them beyond a certain minimum feature size, they don’t quite behave as they should.”

Yet silicon transistors are hard to beat, with an on/off ratio of at least 104 required for practical use. “It’s a pretty high bar to cross,” Ramanathan explains, adding that until now, experiments using correlated oxides have produced changes of only about a factor of 10, or 100 at most, near room temperature. But Ramanathan and his team have crafted a new transistor, made primarily of an oxide called samarium nickelate, that in practical operation achieves an on/off ratio of greater than 105—that is, comparable to state-of-the-art silicon transistors.

In future work the researchers will investigate the device’s switching dynamics and power dissipation; meanwhile, this advance represents an important proof of concept.

“Our orbital transistor could really push the frontiers of this field and say, you know what? This is a material that can challenge silicon,” Ramanathan says.

Solid-state chemical doping

Materials scientists have been studying the family of correlated oxides for years, but the field is still in its infancy, with most research aimed at establishing the materials’ basic physical properties.

“We have just discovered how to dope these materials, which is a foundational step in the use of any semiconductor,” says Ramanathan.

Doping is the process of introducing different atoms into the crystal structure of a material, and it affects how easily electrons can move through it—that is, to what extent it resists or conducts electricity. Doping typically effects this change by increasing the number of available electrons, but this study was different. The Harvard team manipulated the band gap, the energy barrier to electron flow.

“By a certain choice of dopants—in this case, hydrogen or lithium—we can widen or narrow the band gap in this material, deterministically moving electrons in and out of their orbitals,” Ramanathan says. That’s a fundamentally different approach than is used in other semiconductors. The traditional method changes the energy level to meet the target; the new method moves the target itself.

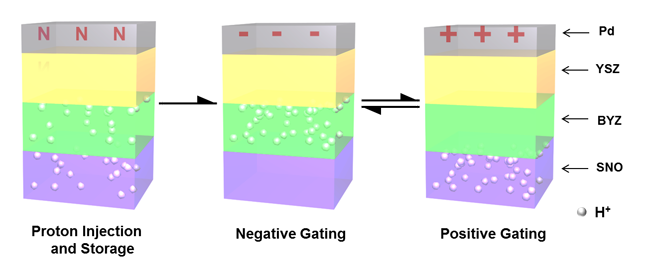

In this orbital transistor, protons and electrons move in or out of the samarium nickelate when an electric field is applied, regardless of temperature, so the device can be operated in the same conditions as conventional electronics. It is solid-state, meaning it involves no liquids, gases, or moving mechanical parts. And, in the absence of power, the material remembers its present state—an important feature for energy efficiency.

“That’s the beauty of this work,” says Ramanathan. “It’s an exotic effect, but in principle it’s highly compatible with traditional electronic devices.”

Quantum materials

Unlike silicon, samarium nickelate and other correlated oxides are quantum materials, meaning that quantum-mechanical interactions have a dominant influence over the material properties—and not just at small scales.

“If you have two electrons in adjacent orbitals, and the orbitals are not completely filled, in a traditional material the electrons can move from one orbital to another. But in the correlated oxides, the electrons repulse each other so much that they cannot move,” Ramanathan explains. “The occupancy of the orbitals and the ability of electrons to move in the crystal are very closely tied together—or ‘correlated.’ Fundamentally, that’s what dictates whether the material behaves as an insulator or a metal.”

Ramanathan and others at SEAS have successfully manipulated the metal-insulator transition in vanadium oxide, too. In 2012, they demonstrated a tunable device that can absorb 99.75% of infrared light, appearing black to infrared cameras.

Similarly, samarium nickelate is likely to catch the attention of applied physicists developing photonic and optoelectronic devices.

“Opening and closing the band gap means you can now manipulate the ways in which electromagnetic radiation interacts with your material,” says Jian Shi, lead author of the paper in Nature Communications. He completed the research as a postdoctoral fellow in Ramanathan’s lab at Harvard SEAS and joined the faculty of Rensselaer Polytechnic Institute this fall. “Just by applying an electric field, you’re dynamically controlling how light interacts with this material.”

Further ahead, researchers at the Center for Integrated Quantum Materials, established at Harvard in 2013 through a grant from the National Science Foundation, aim to develop an entirely new class of quantum electronic devices and systems that will transform signal processing and computation.

Ramanathan compares the current state of quantum materials research to the 1950s, when transistors were newly invented and physicists were still making sense of them. “We are basically in that era for these new quantum materials,” he says. “This is an exciting time to think about establishing the basic, fundamental properties. In the coming decade or so, this could really mature into a very exciting device platform.”

You Zhou, a graduate student at Harvard SEAS, was co-lead author of the paper in Nature Communications. The research was supported by grants from the National Science Foundation (NSF) (CCF-0926148) and the National Academy of Sciences, as well as an NSF Faculty Early Career Development (CAREER) Award to Prof. Ramanathan (DMR-0952794).

Interesting article.

What is stability of the injected protons(H+) in the material as a function of temperature and time?

Sang Kim

In challenging silicon prof. Ramanathan says that “the performance of silicon-based components will hit a wall and traditional silicon transistor have fundamental scaling limits.” In my opinion these statements by prof. Ramanathan are not quite correct. The silicon-based planer bulk technology has ended at 28nm node because of unable to suppress transistor leakage current at 22nm node. It is called short channel effects. That is why FinFET that has a trapizoidal vertical fin structure was invented and developed by Intel at 22nm node in order to suppress the transistor leakage current. The 22nm FinFET is in volume manufactured over two years and 14nm FinFET is manufactured today by Intel. 16nm FinFET will be manufactured by TSMC late this year. The beauty of FinFET is its scalability. The traditional silicon based FinFET is scalable to the end of the roadmap or to 4nm node, suppressing transistor leakage current as well as increasing transistor performance. Therefore, the performance of silicon-based transistor such as FinFETs will not hit a wall and have no fundamental scaling limitations in contrary to what prof. Ramanathan described above. This is an enormous achievement for Intel. Silicon will not be replaced yet.

The silicon based FinFET, however, can’t be extended to 3nm, 2nm and 1nm nodes because of quantum mechanical effects due to such small scales. Therefore, the silicon based 4nm FinFET will be the ultimate or the last transistor manufactured subject to classical device physics suggesting the end of FinFET. Meanwhile, the FinFETs at 3nm, 2nm and 1nm nodes are subject to QM physics, and can’t be manufactured. In QM region or quantum materials the charge carriers such as electrons don’t behave like electron particles, instead behaving like electron weaves. As a result, there are large variations in electrical transfer characteristics such as Vt(increase), on-current, I-on, transistor performance and leakage current….etc.. These point out the end of manufacturability of quantum materials. Therefore, what we have to look for a new contender might be an entirely new device such as tunneling and carbon nanotube based technology away from QM materials, but not necessarily away from silicon.

Misspelling: electron weaves at 5th row from the bottom of 2nd paragraph should be corrected as electron wave.

I think this is another example of misleading and perhaps even misguided hype . To based entire arguments on a single parameters ( On/OFF) ratio is laughable. How about scalability? high frequency performance? repeatability? etc..etc.. Another hype based on a meaningless comparison. The device described s not even a transistor ( a most fundamental amplifying device) but rather one based on ionic conduction ( and hence slow!)

I am afraid scientific integrity has simply given way to Hollywood style announcements to justify funding and seek even more… The demise of silicon has been predicted for the last 30 years by numerous pundits while enjoying its extraordinary power that has changed the way we live.

Yes INTEL, TSMC, SAMSUNG,IBM and Global foundries ( to name a few Si technology giants) can sleep easy… They have heard all this before many times over…