February 9, 2011 — Nanocarbon products include single-walled carbon nanotubes (SWCNT or MWNT) and multi-walled carbon nanotubes (MWCNT or MWNT), fullerenes, graphene, carbon nanofiber and nanodiamonds. Carbon nanotubes are microscopic, tube-shaped structures, which essentially have a composition of a graphite sheet rolled into a tube.

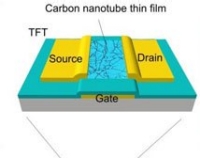

Carbon nanotubes have unique, interesting and potentially useful electrical and mechanical properties, and offer potential for various uses in electronic devices. Carbon nanotubes also feature extremely high electrical conductivity, very small diameters (much less than 100nm), large aspect ratios (i.e. length/diameter ratios greater than 1000), and a tip-surface area near the theoretical limit (the smaller the tip-surface area, the more concentrated the electric field, and the greater the field enhancement factor). These features make carbon nanotubes ideal for electron field emitters, white light sources, lithium secondary batteries, hydrogen storage cells, transistors, and cathode ray tubes (CRTs).

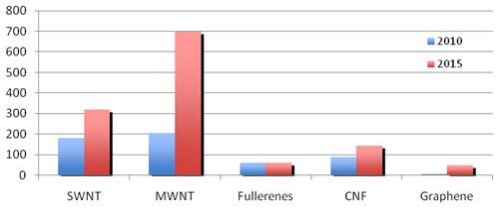

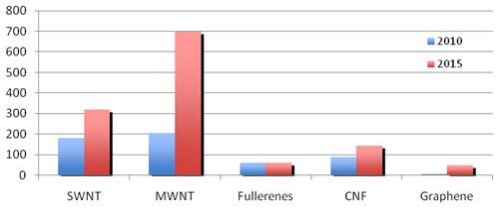

According to a recently published report from iRAP, Inc., ET-113: Production and Application of Carbon Nanotubes, Carbon Nanofibers, Fullerenes, Graphene and Nanodiamonds: A Global Technology Survey and Market Analysis, the production capacity for all products was 4,065 tons in 2010, and is expected to exceed 12,300 tons in 2015. The actual production was less than 25% of the capacity in 2010 and about 50% of the capacity in 2015. Total production value is estimated at about $435 million in 2010 and is expected reach a value of $1.3 billion in 2015.

|

| Share of nanocarbon production value according to types, 2010 and 2015 ($ Millions) Source: iRAP, Inc. |

Production capacity far exceeds actual production. Only about 340 tons of carbon nano products were produced in 2008, about 500 tons in 2009 and about 710 tons are expected to have been produced in 2010, which represents about 17% of capacity. However, actual production is expected to reach more than 9300 tons in 2015, representing a growth rate of 67.3% annually and about 80% of production capacity.

Prices for all products are expected to fall by an average of about 12% a year for the next five years. Growth is chiefly driven by multi-walled carbon nanotubes. World production capacity for multi-wall carbon nanotubes exceeded 390 tons in 2008, reached 1,500 tons in 2009, and is estimated to exceed 3,400 tons per year (tpy) by the end of 2010. Production capacity for MWNT is projected to reach 9,400 tons by 2015.

SWCNTs are the most expensive nano carbon product. They are much more difficult to produce than MWCNTs and are best suited for electronic applications. In 10 to 15 years, SWCNT are expected to replace silicon as the key material in computer chips.

Despite the quickly growing capacity for CNTs, demand has not yet caught up with capacity. However, manufacturers have been increasing capacity to be ready to capitalize on that future demand, which is expected to grow rapidly over the next five to ten years.

For both SWCNTs and MWCNTs, Asia’s production capacity is two to three times higher than that estimated for North America and Europe combined; Japan is the prominent leader in the production of MWCNTs, but China and Korea are rapidly catching up. Use of CNTs in lithium-ion battery electrodes is the current driving force of ton-scale MWCNT production in Japan.

Nanocarbon production value according to types, through 2015 ($ Millions) Source: iRAP Inc.

| |

2010 |

2015 |

AAGR %

(2010-2015) |

| SWNT |

180 |

320 |

12.2 |

| MWNT |

105 |

700 |

46.7 |

| Fullerenes |

61 |

60 |

-0.33 |

| CNF |

88 |

144 |

10 |

| Graphene |

0.75 |

48 |

130 |

| Total |

435 |

1,272 |

24 |

More details of the report are available from Innovative Research and Products (iRAP), Inc., P.O. Box 16760, Stamford, CT 06905, USA, (203) 569-7909, [email protected] or at http://www.innoresearch.net/reportlist.aspx?cid=7

Follow Small Times on Twitter.com by clicking www.twitter.com/smalltimes. Or join our Facebook group

The product has a wafer-like shape compatible with existing automation and wireless communication providing real-time data. APS reduces time locating particle sources, according to the company.

The product has a wafer-like shape compatible with existing automation and wireless communication providing real-time data. APS reduces time locating particle sources, according to the company. The thesis In Silco Studies of Carbon Nanotubes and Metal Clusters has been successfully defended. Supervisor: Professor Kim Bolton. The research has been a collaboration between the University of Gothenburg and the University of Borås. Link to the thesis:

The thesis In Silco Studies of Carbon Nanotubes and Metal Clusters has been successfully defended. Supervisor: Professor Kim Bolton. The research has been a collaboration between the University of Gothenburg and the University of Borås. Link to the thesis: