by Martin G. Selbrede, Uni-Pixel Displays Inc.

Alternatives to silicon-based MEMS displays have the potential to reach new levels of optical performance. These alternatives impose unique demands on thin polymer membranes with respect to electrical, mechanical, and optical performance. New membranes are being developed that meet the requirements for use in field sequential color displays based on frustration of total internal reflection.

September 25, 2009 – Industry interest in field sequential color (FSC) displays has, in part, been driven by the reduction in complexity they make possible. Instead of three separately-driven sub-pixels (one for each primary color) comprising a single conventional pixel (a tricellular pixel), FSC displays generate all colors from a single unicellular pixel by exploiting the temporal resolving properties of the human eye. As a consequence, while FSC displays enjoy reduced complexity in the number of features, their pixel response times must be significantly faster than non-FSC displays. This is especially true if gray scale is achieved digitally using pulse width modulation (PWM), as would likely be true in MEMS-based FSC display systems.

|

| Figure 1. Conceptualization of the layers comprising an AM-LCD system |

The incumbent flat-panel technology, liquid crystal displays (LCD), provides a benchmark for conventional tricellular performance in transmissive display systems. The advantages of a MEMS-based FSC display, relative to a modern LCD system, are not limited to reduced complexity of design. Optical performance, particularly with regard to power efficiency, can be substantially greater for FSC-based MEMS displays. This is a natural result of the large sequence of layers at the heart of LCD systems, most of which serve to attenuate light passing through them. Polarizers, color filters, pixel apertures, all conspire to reduce the final output of an LCD system to a small fraction of the initial light entering the panel from the backlight subsystem (Figure 1).

MEMS-based FSC systems can do without most of the light-attenuating layers that are required for LCD operation, and without these sources of energy attenuation, the power efficiency of MEMS-based FSC displays can exceed that of LCD technology by nearly an order of magnitude (Figure 2). For FSC displays, where the principle of pixel operation is the frustration of total internal reflection [1] (FTIR), most of the source light (theoretically, >60%) makes it through the display layers to the viewer, as compared to 3-8% for most LCD systems. The efficiency of light output for FSC FTIR displays is a design tradeoff. Maximum efficiency is achieved at the expense of display uniformity thus; the overall system design strives to achieve the maximum power efficiency possible without harming the luminous uniformity of the output. Our research has shown that the optimal balance is at 61% efficiency.

The demands upon the polymer membrane at the heart of a polymer MEMS-based display that uses an FSC FTIR approach to light transmission are significant. Optimizing the electrical, mechanical and optical properties of such a membrane is the key to successful implementation of these novel approaches to display fabrication.

|

| Figure 2. Conceptualization of the difference in light attenuation between FSC FTIR display (left) and LCD technology (right). |

Polymer membranes

Uni-Pixel Displays is developing an FSC FTIR display system, called a "time-multiplexed optical shutter" (TMOS), based on a polymer membrane capable of MEMS actuation. The optimization of that technology has led to the creation of Opcuity films, an innovative series of polymer membranes.

The principle of operation of a TMOS display involves suspending a sheet of the new polymer membrane film about one micron above a slab waveguide, using low-optical-impact standoffs at the perimeter of each pixel. In the quiescent, inactive state, the new film remains suspended above the waveguide such that light traveling inside the waveguide, according to the principle of total internal reflection (TIR), is unable to be transferred into the film and redirected out to the observer. The one micron gap places the new polymer membrane film sufficiently far outside the evanescent field of the waveguide [2] to prevent any appreciable light leakage in the pixel off-state.

During pixel actuation, the membrane is electro-statically pulled into contact, or near-contact, with the waveguide. TIR is thereby frustrated and the light that was otherwise contained within the waveguide will pass into the film and be directed out to the viewer. When the electric field is discharged, the film returns to its former position a micron away from the waveguide, causing light transmission to cease.

The three primary colors, red, green and blue, are injected into the waveguide from one (or more) of its edges. Rapid sequential cycling of the primary lights provides the background energy to be modulated by the individual pixels using the principle of PWM. Rapid on-and-off actuation of the film at each pixel makes it possible to achieve a wide color gamut in an FSC PWM display system.

The new polymer membrane films must meet three key physical criteria (mechanical, electrical, and optical) to be suitable for deployment within the targeted polymer-MEMS display system. Balancing these criteria in one planar polymeric structure is central to the new film’s architecture.

– Mechanical criteria for polymer MEMS systems. The mechanical criteria for the polymer MEMS systems are pertinent to rapid actuation over long display lives. Due to the aspect ratio of the pixel (pixel area divided by the one-micron gap between film and waveguide), the actual strains imposed on the elastomer comprising the polymer-based Opcuity film are well under the polymer’s elastic limit, providing a large safe operating area to prevent degradation of the spring constant.

The polymer film, however, must exhibit high mechanical robustness for other reasons. The mechanical stiffness of the membrane has a bearing on the operational voltage of the pixel, and is a power function of the thickness of the film. Some polymer membrane substrates are as thin as three microns and yet must support an array of micro-optical structures on the waveguide-facing surface. Moreover, the mechanical potential energy stored inside membranes during pixel actuation is necessary for returning the pixel to its quiescent state (passive release of the pixel). Passive release allows for simpler architectures; the alternative is active release, whereby the polymer membrane is electrostatically pulled off the waveguide. Currently, all Opcuity films have met the requirements for passive release of actuated pixels.

The final mechanical requirement is that stiction at the point of contact between the polymer membrane and the waveguide be kept to a minimum. The higher the stiction, the greater the energy needed for passive release, which entails higher operating voltages for the display.

– Electrical criteria for polymer MEMS systems. Because the power draw on an electrostatically driven pixel rises exponentially as a function of the gap between the conductors, the polymer membrane must be configured to provide the smallest possible inter-conductor spacing. A TMOS pixel is a variable capacitor, having one capacitance in its quiescent state and a somewhat larger capacitance in its activated state. One plate of the capacitor is a transparent conductor applied directly to the waveguide surface, while the other plate is borne by the membrane.

– Optical criteria for polymer MEMS systems. The optical coupling efficiency of the membrane film is a function of several different parameters. It is actually undesirable for the membrane film to have an excessively high coupling efficiency. However, due to the inherent recycling of light that arises within the slab waveguide — owing to the non-insertion edges being suitably mirrored to keep light inside the waveguide until emitted by a pixel or absorbed at the system sink — a film exhibiting moderate optical coupling efficiency still delivers a global power efficiency of 61% or better.

|

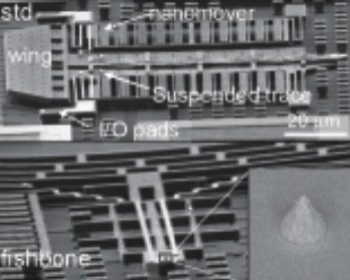

| Figure 3. Photomicrograph showing the micro-optical structures protruding from the interstitial conductor. The flat tips of the frustums have no conductive material on them. |

The surface of the membrane film that faces the waveguide has an array of micro-optical structures integrated into the polymer. These structures are designed to achieve several goals: 1) extract light efficiently from the waveguide; 2) shape the extracted light into an ergonomically useful output distribution; 3) enable efficient final emission to the viewer without undue scattering or absorption; 4) limit the amount of light being coupled based on the effective surface area in contact with the waveguide during pixel actuation; and 5) provide a standoff that keeps the conductor on the membrane film from contacting the conductor deployed on the waveguide.

This last function arises because the conductor is situated between the micro-optical structures (Figure 3). The interstitial conductor between the micro-optical structures (which are conical frustums in the particular sample of membrane film shown in Fig. 3) does not extend to the flat tip of the frustum. When the frustum tips contact the waveguide during pixel actuation, there remains a gap between the conductor on the waveguide and the interstitial conductor situated between the frustums. This feature of the membrane film provides the lowest possible operating voltages for pixel actuation.

The membrane film has applications beyond FSC displays. Films have been designed that have resistance to retaining any fingerprints. Fingerprint-resistant films represent an important additional market for the membrane film.

Membrane films: key to FSC FTIR display systems

Designing optical thin films for deployment in MEMS systems, where the film is expected to be in rapid repeated motion for billions of cycles, is an undertaking that involves the multidisciplinary application of physical and engineering principles. Films that can meet the requirements for these applications enable the furthering of new and novel next-generation displays, such as Uni-Pixel’s TMOS technology, that are able to deliver optical performance at reduced costs. Uni-Pixel’s polymer membrane films are being developed to meet the requirements for next-generation display systems and for production using roll-to-roll fabrication techniques to further reduce manufacturing costs

In principle, active matrix fabrication facilities can be readily converted from LCD manufacturing to TMOS manufacturing, since TFT mother glass serves as a suitable waveguide for many display applications. Laminating the polymer membrane film onto the TFT layer provides for promising new manufacturing opportunities for older fabs.

Conclusion

Uni-Pixel’s FSC FTIR display technology currently exists as a hybrid system that utilizes flexible micro structured film in combination with a TFT rigid glass backplane. We envision that in the future the entire display can become a flexible structure. Any technological barrier to producing an all flexible FSC TMOS display will disappear as printed electronics matures and low-cost reliable TFTs on thin flexible films become available.

Acknowledgments

Opcuity is a trademark of Uni-Pixel Displays Inc.

Biography

Martin G. Selbrede is chief scientist at Uni-Pixel Displays, Inc., 8708 Technology Forest Pl., Ste. 100, The Woodlands, TX USA; ph.: (281) 825-4500; email [email protected]; www.unipixel.com.

References

[1]. S. Zhu, A. W. Yu, D. Hawley, R. Roy, "Frustrated Total Internal Reflection: A Demonstration and Review," Am. J. Phys. 54 (7), pp. 601-607, July 1986.

[2]. F. de Fornel, "Evanescent Waves: From Newtonian Optics to Atomic Optics," first edition, Springer-Verlag, New York, 2001, pp. 18-28.