February 7, 2011 — Sandia National Laboratories will help Mexican engineering students learn to design microelectromechanical devices (MEMS), according to a memorandum of understanding (MOU) between Sandia and the University of Guadalajara.

|

| 10 Mexican professors and 3 Sandia researchers at a SUMMit design course for MEMS devices held at Sandia in December 2009. Ernest Garcia is third from right. (Photo courtesy of Universidad Autonoma de Ciudad Juarez) |

|

The rationale for the agreement is that the economic well-being of Mexico is a national security issue for the United States, said Sandia project lead Ernest Garcia.

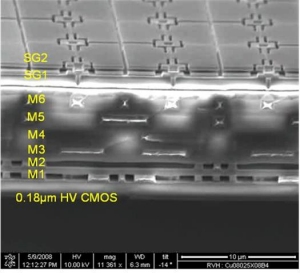

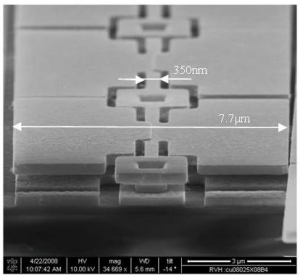

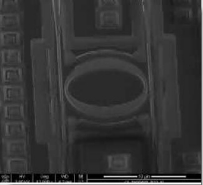

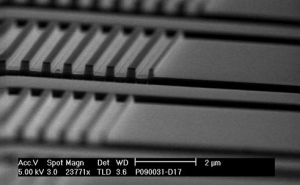

Sandia’s SUMMiT V fabrication process will permit students to design MEMS devices that employ five layers of silicon. Each layer adds another level of complexity to the design. SUMMiT V permits advanced systems created on moveable platforms to be taller (up to 12 micrometers high), stiffer, and more mechanically forceful and robust than those created by earlier processes.

"The University of Guadalajara is like the state of California’s higher education system," Garcia said. "It supports a number of universities throughout the Mexican state of Jalisco. Its leadership wants to use SUMMiT as the basis for a future graduate program in MEMS."

"MEMS manufacturing will leverage many of Mexico’s traditional strengths in electronic manufacturing," Herrera said. "Sandia is in a position to help the University of Guadalajara system migrate to a state-of-the-art MEMS design capability."

"If we could help Mexico improve its research and development capabilities, it would help stabilize its economy," he said. Garcia sees the new collaboration with the U. of Guadalajara as a long-term investment in the future of the Mexican economy. "It’s not a sprint, it’s a marathon," Garcia said, mentioning potential barriers like U.S. controls on exporting technology and intellectual property (IP) to foreign countries.

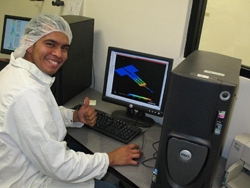

|

| A student in a clean room at the Universidad Autonoma de Ciudad Juarez, which has an ongoing arrangment with Sandia National Labs. Sandia’s MOU with the U. of Guadalajara will open MEMS education to more Mexican students. (Photo courtesy of Universidad Autonoma de Ciudad Juarez) |

|

"Ultimately, the U.S. may be the biggest beneficiary if the MOU contributes to the vitality of the Mexican economy and thereby the stability of the U.S.-Mexican border," said Gil Herrera, director of Sandia’s Microsystems Science, Technology and Components Center. "We believe that Sandia will also benefit from the relationship, as we will have new minds challenging the design envelope of our SUMMiT MEMS technology." Herrera is in charge of Sandia’s activities in support of the collaboration.

Steve Rottler, Sandia’s vice president for basic technologies, signed the agreement for Sandia. He said, "The commitment and enthusiasm of the University of Guadalajara faculty and leadership will greatly help this collaboration to advance technologies vital to the economies and security of both countries."

Similar efforts by Sandia are also underway at Mexican universities in Juarez, Veracruz and Mexico City, as well as the Puebla-based National Institute of Astrophysics, Optics, and Electronics (INAOE).

The agreement extends earlier work by Sandia that played a role in creating a Bi-National Sustainability Laboratory at Santa Teresa, NM, near the border between the United States and Mexico. That effort was intended to examine problems on both sides of the border, such as water rights. The initial goal of the Sustainability Laboratory was to foster research efforts that could ultimately create border industries and jobs to staunch the one-way flow of workers from Mexico to the United States. That effort is now directed by an independent nonprofit corporation supported by a variety of national, state, and corporate sponsors.

The Guadalajara program is expected to expand an existing Sandia-led national MEMS project for Mexico. That country has spent $2 million to fund the project. "Last December, a number of Mexican professors took our MEMS course, licensed our design software, and purchased 100 silicon chips with their MEMS designs," Garcia said.

The Guadalajara agreement is different, Garcia said, because it (and Sandia efforts with other Mexican universities) are in the interior of Mexico rather than near the border.

"We hope eventually to have Mexican universities compete in Sandia’s University Alliance annual MEMS competition for the most imaginative or practical designs," Garcia said. The high-spirited contest, open to institutional members of the Sandia-led MEMS University Alliance program, provides an arena for student engineers to hone their skills in designing and using microdevices. Student contest winners get to see their designs become reality when they are fabricated at Sandia’s MEMS facilities. Last year’s winners were Texas Tech and the University of Utah for creating, respectively, the world’s smallest chess set and a micro barber shop that serviced a single human hair.

A delegation of Mexican professors from Guadalajara will visit Albuquerque in spring 2011 to confer with researchers at Sandia and possibly the University of New Mexico. The trips will be funded by state of Jalisco’s technology office. Albuquerque and Guadalajara are sister cities.

Sandia National Laboratories is a multiprogram laboratory operated and managed by Sandia Corporation, a wholly owned subsidiary of Lockheed Martin Corporation, for the U.S. Department of Energy’s National Nuclear Security Administration. With main facilities in Albuquerque, N.M., and Livermore, Calif., Sandia has major R&D responsibilities in national security, energy and environmental technologies, and economic competitiveness. Learn more at www.sandia.gov

Follow Small Times on Twitter.com by clicking www.twitter.com/smalltimes. Or join our Facebook group