May 12, 2010 – Researchers have come up with a way to calculate and manipulate the effects of Casimir forces, and then use them to keep microelectromechanical systems (MEMS) components from sticking together, which could greatly reduce failure rates and enable new, more affordable devices.

Casimir forces, discovered more than 60 years ago, are quantum forces affecting objects at miniscule distances. At such tiny dimensions, a number of particles flash in and out of existence, with interactions that generally balance out — but at extremely close distances Casimir forces apply to attract particles together. In the 1960s researchers figured out a formula to theoretically describe the effects of Casimir forces on tiny objects, but stopped short of actually solving and evaluating such interactions except for a few examples (e.g. two parallel plates, or more recently a plate and cylinder).

Now, researchers from MIT say they have come up with a way to solve Casimir-force equations for any number of objects with conceivable shape. Their work is published in the Proceedings of the National Academies of Sciences (PNAS). Essentially, effects of Casimir forces on objects <100nm apart can be precisely modeled using objects both 100,000× bigger and further apart that are immersed in a conductive fluid, by calculating the strength of an electromagnetic field at various points around the objects.

"Analytically, it‚s almost impossible to do exact calculations of the Casimir force, unless you have some very special geometries," according to Diego Dalvit, a specialist in Casimir forces at the Los Alamos National Laboratory, in a statement. In principle, the technique, however, "can tackle any geometry. And this is useful."

Very useful, in fact, for MEMS devices, where attractive Casimir forces can cause moving parts to stick together and stop working properly. Earlier this year, the MIT researchers in collaboration with Harvard described an arrangement of materials that enable Casimir forces to cause repulsion in a vacuum. MEMS device design would still require intuition of certain geometries and their properties, though, to know where such repulsion could occur, Dalvit notes.

Note that last year a Harvard-led group examined Casimir forces and how to change the attractive force into a repulsive one — but that work focused on known repulsion for objects in fluids, while the new MIT-led work is about the unexplored area of vacuum-separated objects, explains MIT paper’s lead author Alex Rodriguez. "The ability to obtain Casimir repulsion between vacuum-separated objects was not known and is the subject of much on-going research in this field — as a matter of fact, many scientists believed it was impossible, including myself," he tells Small Times.

|

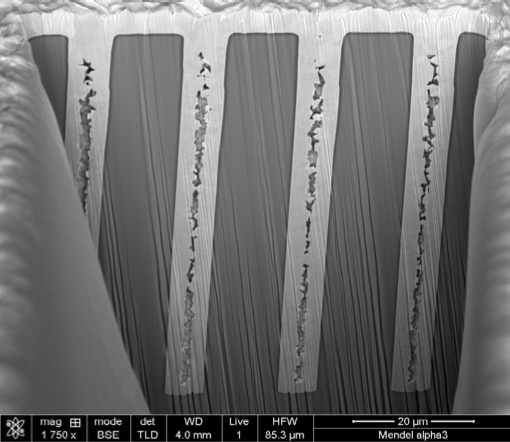

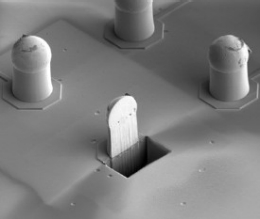

| Though negligible at larger scales, Casimir forces can cause moving parts of micromachines to stick together. (Image: Sandia National Laboratories, MIT) |