June 3, 2011 — Japanese researchers have developed a strain sensor with oriented single-walled carbon nanotube (SWCNT) films bonded to a stretchable polymer substrate. The sensor can measure strains by detecting changes in the films’ electrical resistance.

The CNT strain sensors detect strains of up to 280%, about 50x those detected by conventional metal strain sensors. It is durable for more than 10,000 repeated applications of strains less than 150% and has a 14ms strain response time. The sensor is reportedly less prone to creep than strain sensors made of a composite of an electrically conductive material and a polymer and 20x faster in creep recovery. Sensors comprising a conductive material and polymer detect strains of up to 100%, but undergo creep deformation at high strain rates. It takes more than 100 s before the deformation becomes stable and strain measurements can be made.

|

|

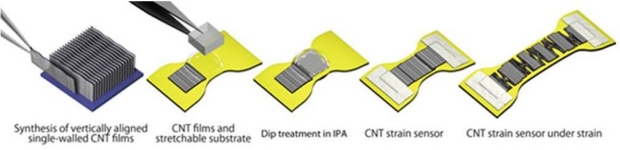

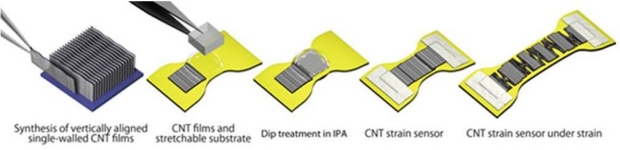

Figure 1. CNT strain sensor fab method.

|

The Nanotube Research Center of Japan’s National Institute of Advanced Industrial Science and Technology (AIST) developed a super growth method to synthesize SWCNTs with high carbon purity (Figure 1). The high-density oriented CNT wafer is created by densification of long, vertically oriented single-walled CNT films in which the CNT films were laid horizontally on a silicon wafer. Mass fabrication of three-dimensional CNT devices was achieved by using this CNT wafer. AIST developed a technique to bond this high-density oriented CNT wafer to a soft polydimethylsiloxane (PDMS, a type of silicone rubber) substrate at any position and in any direction, making it possible to fabricate soft devices combining CNTs and a stretchable polymer substrate.

The CNT orientation is perpendicular to the direction of strains.

The team also developed a bonding technique of a soft electrode, the properties of which remain unchanged after deformation, using an adhesive made of PDMS and conductive rubber with dispersed CNTs synthesized by the super growth method. One electrode is bonded to each end of the CNT strain sensor. The electrode allows researchers to make strain sensors in which all of the components are stretchable, including the electrodes. The largest of the sensors fabricated has been 15 x 5cm.

|

|

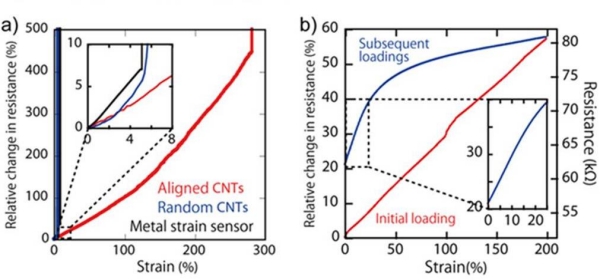

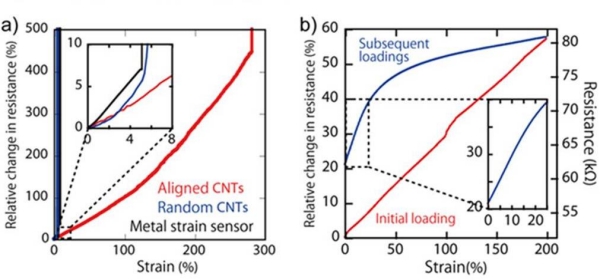

Figure 2. CNT strain sensor properties.

|

CNT sensor properties were measured at room temperature. While a conventional metal strain sensor was able to measure only small strains of up to 5%, the CNT strain sensor was able to measure strains of up to 280% (Fig. 2a). Strain sensors using random-oriented CNTs cannot measure such large strains. On the first application of the strain, the electrical resistance changed with the strain (red line, Figure 2b). On the second and subsequent applications, the electrical resistance changed differently (blue line, Fig. 2b). This curve has two linear sections with different slopes. The sensor was durable for more than 10,000 repeated applications of strains of up to 150% and showed a creep of only about 3% for the rapid application of a 100% strain. The creep became stable in 5 s.

|

|

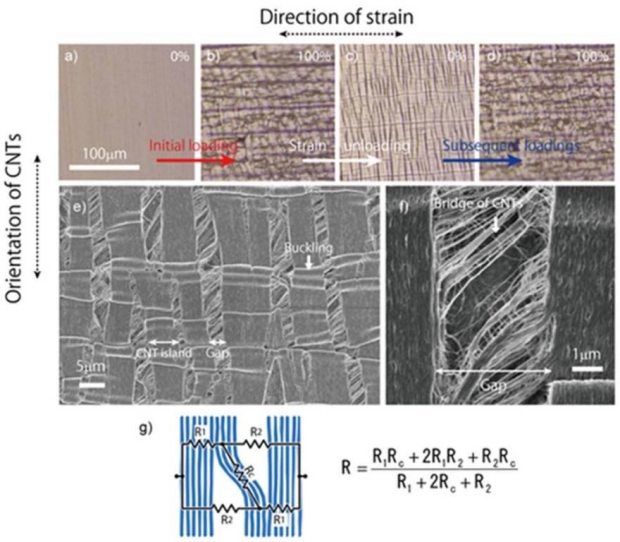

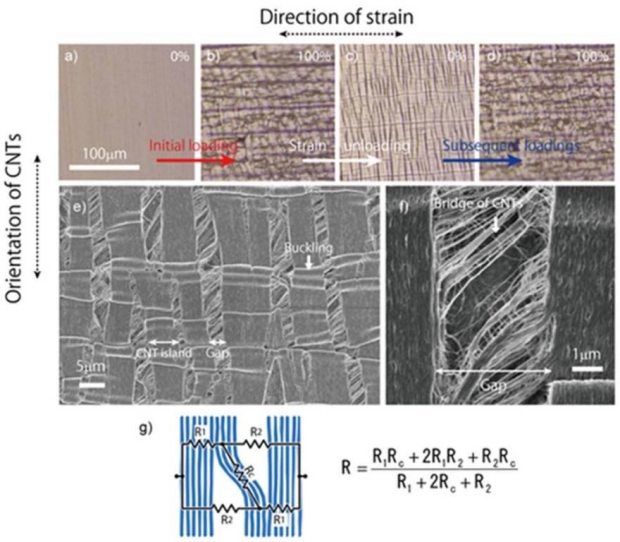

Figure 3. Stretching mechanism of the CNT strain sensor and a model of the change in electrical resistance.

|

The CNT sensor’s surface was observed under a scanning electron microscope (SEM) to study its mechanism. Before strain was applied, no surface irregularities were observed (Fig. 3a). On the initial application of 100% strain, buckling occurred on the CNT surface, causing cracks in the direction perpendicular to the direction of the strain (i.e. in the direction of the CNTs) (Fig. 3b and e). On the second and subsequent applications of the strain, the cracks closed when the strain was removed (Fig. 3c). When the strain was applied again, the cracks that were initially generated opened again (Fig. 3d). The opening and closing of the cracks indicates that the CNTs follow the movement of the stretchable substrate. Detailed SEMs (Fig. 3d) of the crack surface of the CNTs showed that the cracks were bridged by CNTs (Fig. 3f) and conductive paths were provided by the bridges.

Researchers introduced a CNT-bridge model (Fig. 3g) for this mechanism and calculated the change in electrical resistance. The calculated results agreed well with the measured data shown by the blue line in Fig. 2b.

Applications

The CNT strain sensor can be attached to clothing or the body to monitor knee bending and straightening, finger movement, breathing, voice production, etc., for medical or recreational purposes. One example is a data glove, which is a wearable device that could have applications from tele-surgery to immersive gaming. Conventional metal strain sensors can detect only small strains of up to 5% and therefore limit body movement.

|

|

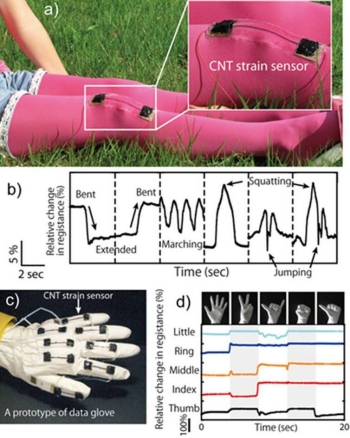

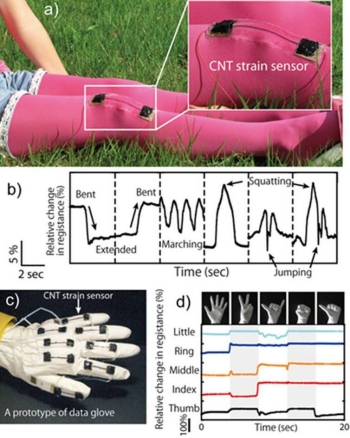

Figure 4. Monitoring knee and finger movement by using the CNT strain sensors.

|

In a measurement using tights to monitor knee movement (Fig. 4a), strain was applied to the sensor when the knee was bent, and the electrical resistance increased. When the knee was straightened, the strain was removed and the electrical resistance decreased. The sensor detected the change in electrical resistance with the change in knee movement (Fig. 4b). It also detected quick bending and straightening movement of the knees in jumping off the ground and knee movement in absorbing shock on landing.

CNT sensors were attached to each finger of a glove (Fig. 4c). When each finger was moved, its shape was identified by the sensor signal, demonstrating that the sensor can be applied to a data glove (Fig. 4d). As the CNT strain sensor is a highly durable device, the tights and the glove can be used repeatedly by multiple users.

Details of the study were published online in March 2011 in Nature Nanotechnology. Access the article here: http://www.nature.com/nnano/journal/v6/n5/full/nnano.2011.36.html

This study was conducted as part of the research project, "Functional Integrated CNT Flexible Nano MEMS Devices Fabricated by Self-Assembling Processes," (Research Director: Kenji Hata) in the research area, "Creation of Nanosystems with Novel Function through Process Integration" (Research Supervisor: Junichi Sone, VP, National Institute of Materials Science) of the Core Research of Evolutional Science and Technology. This project is funded by the Japan Science and Technology Agency.

The team will seek to collaborate with businesses to develop devices for commercial applications.

Team: Takeo Yamada (Senior Researcher), Super Growth CNT Team (Leader: Kenji Hata), the Nanotube Research Center (Director: Sumio Iijima) of the National Institute of Advanced Industrial Science and Technology (AIST; President: Tamotsu Nomakuchi)

Follow Small Times on Twitter.com by clicking www.twitter.com/smalltimes. Or join our Facebook group

The TMP006 digital temperature sensor can be used to accurately measure a smartphone, tablet, or other device’s case temperature, or to measure external temperature outside the device. It is an entirely digital product for contactless temperature measurement that is 95 percent smaller than other thermopile sensors, as it integrates the MEMS sensor and supporting analog circuitry.

The TMP006 digital temperature sensor can be used to accurately measure a smartphone, tablet, or other device’s case temperature, or to measure external temperature outside the device. It is an entirely digital product for contactless temperature measurement that is 95 percent smaller than other thermopile sensors, as it integrates the MEMS sensor and supporting analog circuitry. PlasmaPro Estrelas100’s process flexibility enables use in R&D labs building nano and micro structures. The hardware can run Bosch and cryo etch technologies in the same chamber. The tooling meets fabrication needs of existing — accelerometers, gyroscopes — and emerging — pico projectors, energy harvesters, micro fuel cells — MEMS devices. The system is compatible with 50-200mm wafers, so devices can go to production using the same chamber hardware as development.

PlasmaPro Estrelas100’s process flexibility enables use in R&D labs building nano and micro structures. The hardware can run Bosch and cryo etch technologies in the same chamber. The tooling meets fabrication needs of existing — accelerometers, gyroscopes — and emerging — pico projectors, energy harvesters, micro fuel cells — MEMS devices. The system is compatible with 50-200mm wafers, so devices can go to production using the same chamber hardware as development.