January 26, 2011 — An international team of scientists led by King’s College London has taken a step closer towards developing optical components for super-fast computers and high-speed Internet services of the future. This has the potential to revolutionize data processing speeds by transmitting information via light beams rather than electric currents.

|

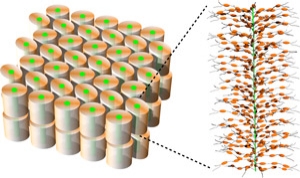

| Artistic impression of metamaterial structure consisting of gold nanorods illuminated by two interacting light beams. Courtesy of R. McCarron |

The researchers are studying the science of ‘nanoplasmonic devices,’ whose key components are tiny nanoscale metal structures, more than 1000 times smaller than the size of a human hair, that guide and direct light.

Information is routinely sorted and directed in different directions to allow computing, Internet connections, or telephone conversations to take place. At present, however, computers process information by encoding it in electric signals.

It would be much faster to process and transmit information in the form of light instead of electric signals, but until now, it has been difficult for the light beams to be ‘changed,’ that is to interact with other beams of light, while travelling through a material, and this has held up progress.

The scientists have solved this by designing a new artificial material, which allows light beams to interact efficiently and change intensity, therefore allowing information to be sorted by beams of light at very high speeds. The structure of the tailor-made material is similar to a stack of nanoscale rods, along which light can travel and interact.

Professor Anatoly Zayats, in the Department of Phyics at King’s, explains: "If we were able to control a flow of light in the same way as we control a flow of electrons in computer chips, a new generation of data processing machines could be built, which would be capable of dealing with huge amounts of information much faster than modern computers.

"The new material we have developed, often called ‘metamaterial,’ could be incorporated into existing electronic chips to improve their performance, or used to build completely new all-optical chips and therefore revolutionize data processing speeds.

"While there are many challenges to overcome, we would anticipate that in the future this faster technology could be in our PCs, mobile phones, aeroplanes and cars, for example."

Other members of the team involved in this latest research include Argonne National Laboratory in the USA; University of North Florida; University of Massachusetts at Lowell; and Queen’s University of Belfast in the UK.

The Engineering and Physical Sciences Research Council (EPSRC) is funding the £6 million research programme at King’s, Queen’s University Belfast and Imperial College London.

The research is published in the journal Nature Nanotechnology. The paper ‘Designed ultrafast optical nonlinearity in a plasmonic nanorod metamaterial enhanced by nonlocality’ is published on Nature Nanotechnology’s website at http://www.nature.com/nnano/journal/vaop/ncurrent/full/nnano.2010.278.html

For further information, visit http://www.activeplasmonics.org/

King’s College is research led and has nearly 23,000 students (of whom more than 8,600 are graduate students) from nearly 140 countries, and some 5,500 employees. King’s is in the second phase of a £1 billion redevelopment programme transforming its estate.

Follow Small Times on Twitter.com by clicking www.twitter.com/smalltimes. Or join our Facebook group