by Wenbin Ding, Yole Développement

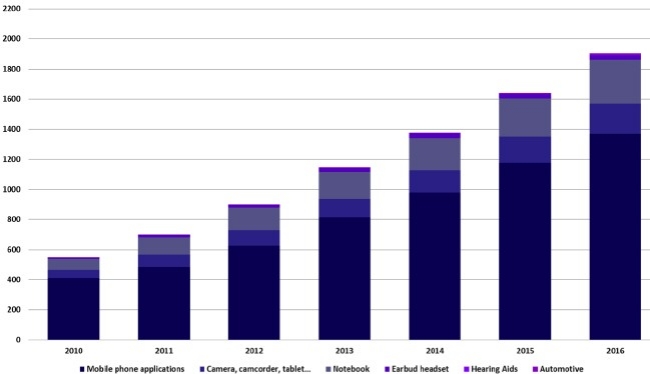

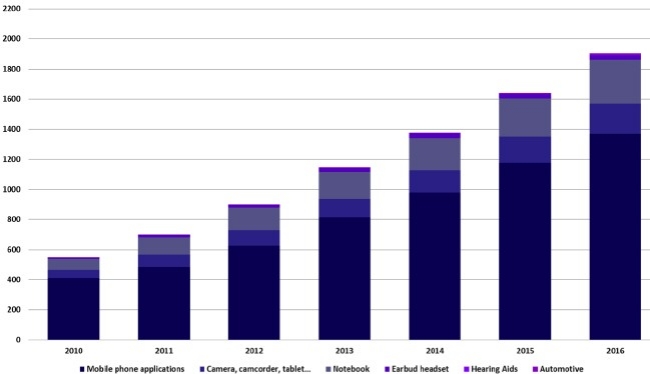

June 2, 2011 – Demand for higher-quality sound and smaller devices will propel 23% compound average growth (CAGR) for MEMS microphones for the next five years, creating market volumes of some 2 billion units a year by 2016, for a roughly $500M business. A sign of the rate of growth: it took mic market pioneer Knowles six years to sell 1 billion units, but only 18 months more to hit the 2 billion mark in May of this year. And plenty of companies are scrambling for a piece of this growing market.

There’s lots of room for growth. MEMS microphones are still in less than 20% or so of mobile phones, but we expect that to reach 40% of phones by 2015-2016. Most voice phones still opt for lower-cost electret condenser microphones, but smart phones — with a big push from Apple’s lead example — need the higher-quality MEMS mics, and also sell for higher prices that can better cover the cost.

The applications for MEMS microphones are also growing. Notebook computers are now starting to adopt the smaller MEMS versions for the better sound, as are tablets of course, and camcorders and cameras with video options.

And demands are also getting more sophisticated, pushing the market towards the MEMS devices for multi sensor solutions for active noise cancellation, and for digital mics for less disruption from RF and EMI. Some handsets in the smart phone market are now starting to use two or more mics for noise cancellation to improve sound quality, while some notebooks use microphone array to better capture sound from users apt to not be directly in front of the microphone. Computers need digital mics to avoid interference. More sophisticated smart phones and tablets will likely increasingly adopt digital mics as well starting from about 2012, when other applications like camcorders and tablets will eventually move to multiple mics as well.

The MEMS devices continue to scale down sharply in size and in cost. By 2010 Knowles had reduced die size by 50% from 2006, for presumably twice the die per wafer, without reducing the size of the microphone diaphragm. Akustica’s latest one-chip solution from its CMOS process is only 0.70mm2. Epcos (TDK-EPC) meanwhile is using flip-chip instead of wire bonding for a thinner package.

MEMS microphone pioneer Knowles now dominates the market with more than 80% share, capitalizing on its strong background in the microphone and audio components business, its strong IP protection for its early packaging solution, its high-volume manufacturing, and a solid brand name consumer gear makers can trust — complete with the all-important used-by-Apple cachet. A crowd of challengers aims to get a piece of this growing market, both companies from the ECM microphone business, and MEMS makers. The field is littered with companies who dropped out after the first flush of interest in MEMS microphones several years ago, and with other suppliers who have yet to make significant inroads into the market — MEMS as usual have proved difficult to ramp in volume, and breaking in to the high-volume consumer phone market isn’t easy. But the current crop of both Asian ECM makers and major MEMS suppliers are likely better positioned for the challenge, as the MEMS microphone market is now well-established, and MEMS manufacturing technology is more mature.

|

MEMS microphone market forecast, split by application (in millions

of units), 2010-2016. CAGR is 23%. (Source: Yole Développement) |

MEMS manufacturing technology will be a focus of this year’s program at SEMICON West’s TechXPOTs: a Tuesday morning (July 12) session on "The future of MEMS: Moving from a niche to a mainstream business" (presented in cooperation with the MEMS Industry Group), and a Tuesday afternoon session on "Heterogeneous integration with MEMS and sensors." Plus exhibits and technical sessions at the Extreme Electronics TechZONE.

The TMP006 digital temperature sensor can be used to accurately measure a smartphone, tablet, or other device’s case temperature, or to measure external temperature outside the device. It is an entirely digital product for contactless temperature measurement that is 95 percent smaller than other thermopile sensors, as it integrates the MEMS sensor and supporting analog circuitry.

The TMP006 digital temperature sensor can be used to accurately measure a smartphone, tablet, or other device’s case temperature, or to measure external temperature outside the device. It is an entirely digital product for contactless temperature measurement that is 95 percent smaller than other thermopile sensors, as it integrates the MEMS sensor and supporting analog circuitry. PlasmaPro Estrelas100’s process flexibility enables use in R&D labs building nano and micro structures. The hardware can run Bosch and cryo etch technologies in the same chamber. The tooling meets fabrication needs of existing — accelerometers, gyroscopes — and emerging — pico projectors, energy harvesters, micro fuel cells — MEMS devices. The system is compatible with 50-200mm wafers, so devices can go to production using the same chamber hardware as development.

PlasmaPro Estrelas100’s process flexibility enables use in R&D labs building nano and micro structures. The hardware can run Bosch and cryo etch technologies in the same chamber. The tooling meets fabrication needs of existing — accelerometers, gyroscopes — and emerging — pico projectors, energy harvesters, micro fuel cells — MEMS devices. The system is compatible with 50-200mm wafers, so devices can go to production using the same chamber hardware as development.