May 31, 2011 — Micro-cantilevers can measure lipid bilayers interactions with surfactants with a new level of sensitivity, say Rice University researcher Sibani Lisa Biswal, assistant professor in chemical and biomolecular engineering, and Kai-Wei Liu, a graduate student in Biswal’s lab.

Lipid bilayer membranes surround living cells and work with specific membrane proteins as "gate keepers": letting ions, proteins and other essential molecules into the cell. Individual lipid molecules in the bilayer have a hydrophilic head and two hydrophobic tails. They aggregate into two-layered sheets, with the heads pointed out and the hydrophobic tails pointed inward.

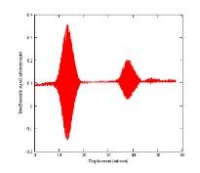

Liu and Biswal have previously worked on attaching lipid bilayers to microcantilevers. A protective coating on the thin gold layer makes the top of the cantilever inert, so the membranes attach themselves to and spread out over the silicon dioxide bottom. The membrane’s interaction with the cantilever affects surface tension, bending the cantilever enough to be measured by a laser sensor with nanometer resolution.

In their current work, the researchers introduced varying concentrations of lysolipids to the supported lipid bilayers. Lysolipid compounds lower liquids’ surface tension, and have a hydrophilic head but only one hydrophobic tail. They are surfactants that can be used in detergents, among other applications. Based on the experimental results, measured by the micro-cantilevers, detergents could be fine tuned to better destroy stains.

"The cantilever naturally wants to bend with whatever force the membrane puts on it," Biswal said. Cantilever structures are the simplest micro-electromechanical systems (MEMS) that can be easily micromachined and mass-produced.*

In low concentrations, lysolipid molecules wedge themselves into the bilayer, while their hydrophobic tails join up to the membrane’s hydrophobic inner ring; changing the surface tension on the cantilever, Liu and Biswal found.

In high concentrations, lysolipid monomers form micelles, rings of molecules that interact with the membranes and disrupt the hydrophobic interactions that keep them together. Depending on their strength (determined by the chemical makeup of their hydrophobic tails), the micelles can either weaken the membranes by pulling lipid molecules away or destroy the membranes completely.

Biswal sees other potential for the technique. "We’re interested in using this as a general platform for looking at small molecules," she said.

Liu is studying how hepatitis C peptides behave in the presence of a microcantilever-mounted membrane. "This could be a way to probe how viruses are able to enter cell membranes or disrupt proteins on their surfaces," she said.

Biswal suggested that carbon-60 atoms — buckyballs — might also be a good subject, because they are naturally hydrophobic. Research on buckyballs could advanced understanding of nanomaterial/cell interaction.

Results were reported online in the American Chemical Society journal Analytical Chemistry. Access the article here: http://pubs.acs.org/doi/abs/10.1021/ac200401n

The Robert A. Welch Foundation funded the research.

Learn more at www.rice.edu

Follow Small Times on Twitter.com by clicking www.twitter.com/smalltimes. Or join our Facebook group

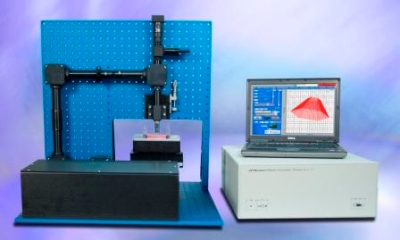

The Laser µFAB is designed for use in additive and subtractive processes, including two-photon polymerization (TPP) during 3D microfabrication, laser ablation and surface structuring of various materials, volumetric writing, and nanosurgery/microdissection. Researchers use TPP to develop photoresists for photonics, microelectronics, and MEMS. The tool ablates and structures metals, polymers, semiconductors, glasses, ceramics, and biological targets. Waveguides and microfluidics can be volumetrically written in glass or polymer substrates.

The Laser µFAB is designed for use in additive and subtractive processes, including two-photon polymerization (TPP) during 3D microfabrication, laser ablation and surface structuring of various materials, volumetric writing, and nanosurgery/microdissection. Researchers use TPP to develop photoresists for photonics, microelectronics, and MEMS. The tool ablates and structures metals, polymers, semiconductors, glasses, ceramics, and biological targets. Waveguides and microfluidics can be volumetrically written in glass or polymer substrates. May 24, 2011 — Sunrise Optical LLC debuted the Zebraoptical low coherence fiber optic interferometer with microscope attachment. The Zebraoptical Integrated Metrology Tool (ZIMT) provides metrology readings on

May 24, 2011 — Sunrise Optical LLC debuted the Zebraoptical low coherence fiber optic interferometer with microscope attachment. The Zebraoptical Integrated Metrology Tool (ZIMT) provides metrology readings on