by Jan Provoost, science editor, imec

May 26, 2011 – At imec’s technology forum, Eric Dy, business development manager at imec, talked about the opportunities that advanced electronics can create in healthcare — to improve the efficiency and cost of the current medical practice, but also opportunities for new, disruptive research and treatments.

Currently, 70% of the diagnostic decisions are based on the results of lab tests. Molecular diagnostics often involves labor-intensive work with expensive machines. Considering the results of R&D work in imec and other research centra on labs-on-chip, there is a huge opportunity here to replace some of the tasks in the labs with mass-produced point-of-care equipment that give immediate feedback.

Going a step further: if we can mass-produce microdevices for molecular diagnostics, then the medical community will have access to a large amount of data that they can use to develop more predictive and personal treatments. Treatments that are based on cheap, personal molecular diagnostics.

imec is one of the few research centres where all the expertise and abilities needed to create the next wave of e-health comes together, Dy pointed out. Innovative circuit design, biosensors, wireless R&D, low-power ICs, biointerfacing — all are present, connected in an R&D ecosystem including such stakeholders as hospitals and medical device manufacturers.

Dy also showcased some of the technologies that will benefit the medical research community. One of the highlights is interfacing between biology and electronics. An example is a platform for high-content screening of molecules and tissues, consisting of an IC with a surface that allows cells to attach and grow, and to communicate through microsized electrodes with the underlying circuitry. Electronics as these will, according to Eric Dy, "help scientists do research that was not possible to do before."

| CMOS chip with micronail electrode array for single- cell stimulation and recording. (Source: imec) |

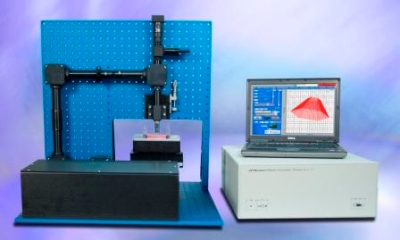

The Laser µFAB is designed for use in additive and subtractive processes, including two-photon polymerization (TPP) during 3D microfabrication, laser ablation and surface structuring of various materials, volumetric writing, and nanosurgery/microdissection. Researchers use TPP to develop photoresists for photonics, microelectronics, and MEMS. The tool ablates and structures metals, polymers, semiconductors, glasses, ceramics, and biological targets. Waveguides and microfluidics can be volumetrically written in glass or polymer substrates.

The Laser µFAB is designed for use in additive and subtractive processes, including two-photon polymerization (TPP) during 3D microfabrication, laser ablation and surface structuring of various materials, volumetric writing, and nanosurgery/microdissection. Researchers use TPP to develop photoresists for photonics, microelectronics, and MEMS. The tool ablates and structures metals, polymers, semiconductors, glasses, ceramics, and biological targets. Waveguides and microfluidics can be volumetrically written in glass or polymer substrates. May 24, 2011 — Sunrise Optical LLC debuted the Zebraoptical low coherence fiber optic interferometer with microscope attachment. The Zebraoptical Integrated Metrology Tool (ZIMT) provides metrology readings on

May 24, 2011 — Sunrise Optical LLC debuted the Zebraoptical low coherence fiber optic interferometer with microscope attachment. The Zebraoptical Integrated Metrology Tool (ZIMT) provides metrology readings on