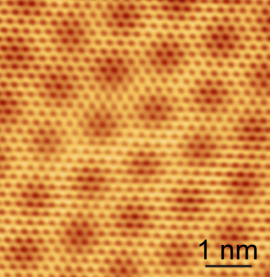

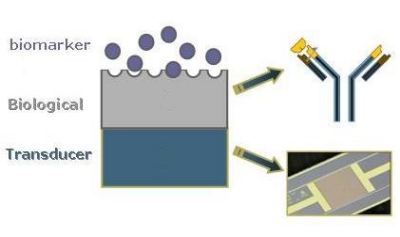

March 9, 2011 — SouthWest NanoTechnologies’ (SWeNT) single-wall carbon nanotubes (SWCNT) exhibit promising potential for use in biomedical treatments such as cancer photo thermal therapies, new research reveals. The key is the CNT’s ability to enter the cytoplasm without toxic effects, then cause apoptosis when radiated with a 980nm laser.

According to an article published in Biophotonics and Immune Responses, researchers in China and the U.S. showed that SWeNT SWcNT "possessed superior nanoscale interactions and physical properties that make them useful in various biological systems."

One intrinsic property of SWCNTs is their strong optical absorbance in the near-infrared (NIR) of the spectrum. As a result, they can be used to selectively increase thermal destruction in target tumors. The SWeNT SWCNT has an intense absorption band at 980nm. When radiated with a 980nm laser, these tubes affect cellular oxidation and destroy the mitochondrial membrane potentially causing apoptosis, or programmed cell death.

"The SWCNTs appear to enter the cytoplasm without cytotoxic effects in cells, and can be used as effective and selective nanomaterials for cancer photo thermal therapy," explains Wei R. Chen, a researcher at the University of Central Oklahoma. "The distinct architecture of the SWCNT can shuttle various molecular cargoes, including anticancer drugs and proteins, crossing through cellular membrane without cell disruption."

"We’re excited by the findings that SWeNT SWCNT killed the cancer cells and didn’t harm the healthy ones," said SWeNT CEO Dave Arthur. "These findings distinguish the qualities and special properties of our…Specialty Multi-Wall (SMW) carbon nanotubes [for biomedical applications]."

The research is supported by the National Basic Research Program of China, the Program for Changjiang Scholars and Innovative Research Team in University and the National Natural Science Foundation of China.

Feifan Zhou1, Da Xing1*, Wei R. Chen1,2, Direct Imaging the Subcellular Localization of Single-Walled Carbon Nanotubes Biophotonics and Immune Responses, Biophotonics and Immune Responses: http://spie.org/x648.html?product_id=874307

1. MOE Key Laboratory of Laser Life Science & Institute of Laser Life Science, College of Biophotonics, South China Normal University, Guangzhou 510631, China

2. Biomedical Engineering Program, Department of Engineering and Physics, College of Mathematics and Science, University of Central Oklahoma, Edmond, OK 73034, USA

SouthWest NanoTechnologies, Inc. (SWeNT) is a specialty chemical company that manufactures high quality single-wall and specialty multi-wall carbon nanotubes, printable inks and CNT-coated fabrics for a range of products and applications including energy-efficient lighting, affordable photovoltaics, improved energy storage and printed electronics. For more information, visit www.swentnano.com

Follow Small Times on Twitter.com by clicking www.twitter.com/smalltimes. Or join our Facebook group

The VEGA 3 includes high-performance electronics for faster image acquisition (down to 20ns/pixel) and signal processing, an ultra-fast scanning system with compensated static and dynamic image aberrations, an extended range of scanning modes using the original Wide Field Optics, In-Flight Beam Tracing for real-time beam optimization, updated software control with high level of automation, and built-in scripting for user-defined applications. The proprietary Intermediate Lens (IML) works as an "aperture changer." The column design, without any mechanical centering elements, allows fully automated column set-up and alignment. Live stereoscopic imaging, using the advanced 3D Beam Technology, enables 3D viewing and navigation of micro- and nanoscale subjects. Jaroslav Klima, CEO of TESCAN, noted that the SEM will perform easily in the leading-edge research arena with multiple users.

The VEGA 3 includes high-performance electronics for faster image acquisition (down to 20ns/pixel) and signal processing, an ultra-fast scanning system with compensated static and dynamic image aberrations, an extended range of scanning modes using the original Wide Field Optics, In-Flight Beam Tracing for real-time beam optimization, updated software control with high level of automation, and built-in scripting for user-defined applications. The proprietary Intermediate Lens (IML) works as an "aperture changer." The column design, without any mechanical centering elements, allows fully automated column set-up and alignment. Live stereoscopic imaging, using the advanced 3D Beam Technology, enables 3D viewing and navigation of micro- and nanoscale subjects. Jaroslav Klima, CEO of TESCAN, noted that the SEM will perform easily in the leading-edge research arena with multiple users.